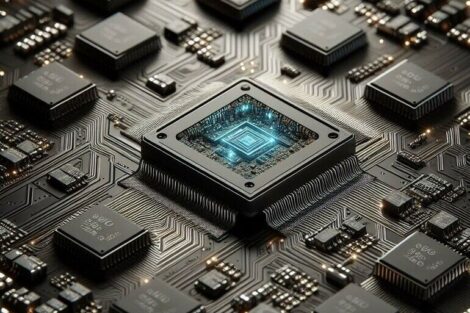

Alpha WS-819 water-soluble, lead-free solder paste from Cookson Electronics Assembly Materials delivers very good printing characteristics over a wide range of humidity (50 % +/- 15 %) conditions, while offering excellent cleanability and resistance to voiding. It is reportedly the first water-soluble, lead-free solder paste that meets each of these requirements, and it was developed specifically to meet the needs of electronic assemblers challenged to manufacture lead-free PCBs for ultra-high reliability applications.

The product helps lower soldering costs by providing very good stencil life, reduced printing cycle time, excellent voiding resistance, and easy water cleaning without the added cost of saponifiers and special waste water treatment and disposal systems. “Our customers tell us that to achieve high throughput and yield results, they must pay special attention to a core group of Key Process Indicators (KPI) in their water-soluble, lead-free assembly process,” said Mitch Holtzer, Cookson’s Global Product Manager. “We developed ALPHA WS-819 paste which performs very well on these KPIs: stencil life, print cycle time, easy water cleaning and voiding resistance.”

The solder paste has been tested on a number of surface finishes, including Entek Plus HT organic solderability preservative, AlphaSTAR immersion silver, immersion tin and ENIG finishes.

EPP Europe 422

Share: