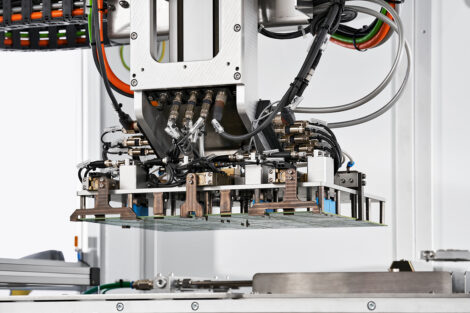

Void less, flux less, ultra clean: The VLO 20 vacuum soldering system from centrotherm thermal solutions meets the highest demands of R&D departments as well as the needs of small production facilities which use vacuum to achieve void less soldering joints. With the vacuum soldering system, the soldered area affected by voids can be reduced to less than 2 %, typical reflow soldering systems range at 20 %. This system is ideal for production facilities which run flux less and void less soldering processes with various gas atmospheres N2, H2 up to 100 %, N2/H2 95/5 %). It can also provide wet chemical activation with HCOOH and dry chemical activation with RF plasma for ultra clean soldering joints. Even lead free paste or pre-forms can be used without additional flux.

The system features process temperature up to 450 °C, heating ramp up to 50 K/min, cooling rate up to 180 K/min and a vacuum level up to 10-2 mbar. It has a short cycle time. The process control computer comes with a user-friendly touch screen for operating, process profile editing and recipe storing. A serial interface lets users transfer data to PCs for offline programming and remote service monitoring. The soldering system is optionally available with lamp heating (radiation) for increased heating-up. Typical applications of the vacuum soldering equipment are: power semiconductors, optoelectronic packaging, hybrid microelectronic assemblies, hermetic package sealing, wafer level packaging, MEMS package sealing and UHB LED packaging.

EPP Europe 418

Share: