Over time, PC-based machine control has encroached upon, and ultimately gained dominance over traditional, reliable PLC controllers. There are many different reasons for this, but perhaps the most important benefit directly attributable to this development has been the enabling of advanced manufacturing systems and technologies that would not have been possible had it not been for the evolution of PC control.

Michael L. Martel, for Sensoray, Portland, OR, USA

Many OEMs endeavor to incorporate advanced capabilities and control into their systems to improve functionality, data acquisition, analysis, and more with the goal of giving their systems an added ‘edge’ over comparable competitive systems on the market. Because of this, OEMs are also reluctant to discuss their transition from PLC equipment (programmmable logic control for loop feedback) to PC control for their industrial manufacturing or inspection systems, and that’s understandable because of the options involved.

One global supplier of sophisticated inspection and process quality control systems to the bottling industry delivers a good and real example for the evolution of the automation equipment. Though the OEM prefers to remain unnamed in this instance, their machines perform multiple functions including glass container inspection. The company’s flagship line of visual inspection machines have been entirely PC controlled to date utilizing amultifunction analog/digital I/O PCI card from Oregon-based Sensoray, an industry-leading designer and manufacturer of OEM electronics for video imaging, data acquisition and industrial control. The OEM’s designers incorporated Sensoray’s Model 626controller into their product lines due to the much greater flexibility and functionality of the PC over PLC control. But now, the emergence of the new Model 826 more powerful controller with its much greater capabilities has allowed this OEM to launch a new software technology advancement that improves and simplifies container inspection for all of their flagship line. Thus, advanced PC control enables multi-complex data acquisition and analysis needed for machine vision automated inspection, which is the heart of these capable inspection systems.

PLC – reliable, simple

A programmable logic controller, or PLC, is a computer used for automation of typically industrial electromechanical processes, such as control of machinery on factory assembly lines, amusement rides, or light fixtures. PLCs are used in many machines and in numerous industries. First introduced in the 1970s and still in widespread use today, PLCs have dominated the process and automation control marketplaces. But since the early 1990s, PC-based control has been encroaching on PLC dominance due to, in part, greater capability (increases in processor speed and range, as well as system functionality) and, quite importantly, greater robustness required by the demanding industrial manufacturing environment. Greater cost-competitiveness (lower cost of components) has leveled the playing field somewhat as well. Increasing numbers of applications utilizing a PC have also paved the way.

PLCs began as a basic and reliable alternative to such as electro-mechanical relays, with limited functionality, and in time evolved to include such capabilities as motion control, advanced PID (proportional–integral–derivative) process control and other functions. Since they were designed for the harsh industrial environment, when PC control began to compete, safety was the biggest argument in favor of the PLC and, depending on the operating environment, can be a major concern for the user. It is vital in cases where human interaction with the machine could be potentially dangerous, and when safety standards in a fab or factory are crucial to machine acceptance. For example, if a PC controller failed or crashed, which was much more commonplace earlier in the advent of PC-based systems, the results could be disastrous; a damaged or destroyed machine, line, product, or even an injured operator, depending on what was being controlled. Thus, many machine designers stayed with the steady and known reliability of the PLC with its significantly lower potential for such failures.

The PC controller did however perform an important role in that it was used primarily for complex calculations, monitoring, measuring and factory networking as well as being a comfortable user-interface to the PLC system. It was usually housed in a more environmentally-controlled location because it couldn’t operate as reliably as a PLC in the less-friendly factory environment. The PC eventually evolved to include PLC functionality.

Making choices

Now, the PC-based systems have become more robust, hardened for operating in the harsh industrial environments that were once only suitable for the PLC. Similarities and cross-over functionality between the PC and PLC, which has not stood still in refinement as the PC controller gained ground, have grown and are somewhat matching. The situation is such that the machine designer today faces a quandary in choosing between two types of controller that have seen a good deal of functional convergence.

The specifier can simplify the choice by analyzing and comparing eight major areas of differentiation:

- Operation

- Robustness

- Serviceability

- Hardware integration

- Security

- Safety

- Programming

- Cost difference

Operation

PLC: Features an embedded real-time operating system (RTOS) with a dedicated processor that ensures a high degree of control system reliability. Its task is only to handle automation and/or a process.

PC: With a real-time kernel or real-time OS, the PC can accomplish the same reliability and speed of control as a PLC. The software running the PC is dedicated to automation and will therefore have a minimal chance of lock-ups.

Robustness

PLC: The standard off-the-shelf PLC has no moving parts and thus can withstand harsh (e.g. vibration) environments for millions of cycles.

PC: Can contain some moving parts such as fans or hard disk drives, not a good match for vibration. But hardened industrial versions offer options such as solid state drives, fanless cooling and in-cabinet mounting, making them just as durable and robust as a PLC overall.

Serviceability

PLC: External devices can generally be replaced quickly and with ease while the system is in operation (hot-swapped).

PC: Not as easy; changing out a PCI board in the computer may require workstation downtime.

Hardware integration

PLC: Both the PLC and PC have the ability to control a multitude of devices using familiar industrial communication networks and more modern Ethernet-based counterparts. PLC has many of these options built-in.

PC: The PC is equipped with a more open array of interfaces such as USB, Ethernet, etc., giving the user access to more off-the-shelf devices to handle tasks that a PLC could not usually manage. One example is the utilization of an advanced hi-res imaging system where the images would be stored, in real time analyzed, compared and possibly archived. The PC is better suited here due to the sophisticated nature of the task and the amount of memory required, while a PLC would have limited storage and processing capabilities.

Security

PLC: Traditionally, a PLC is less exposed to unauthorized access from the outside, and due to its dedicated OS, very few instances are known of virus attacks on PLCs (even though they are not actually immune).

PC: Although far more susceptible to virus attacks than a PLC, strict security measures can be taken to significantly reduce potential threats, and standard software is available to detect and remove viruses and alike.

Safety

PLC: The PLC has designated communication channels to slave devices to tightly monitor operation, as well as additional integrated electrical devices to allow for redundancies.

PC: Integrated safety has, for example, become available on Sensoray PC-based platforms, including the Model 626 and 826 PCI board controllers with Ethernet field bus design with built-in electrical isolation, which eliminates the ground loops that commonly plague other field buses. Many control systems employ solid state relays (SSR) to control high-power devices such as motors, solenoids and lights; thus, the ability to control these relays via Ethernet is highly desirable, because it adds a layer of ‘fail-safe operation’ to that control. Relays often control devices that must be turned off in a fail-safe manner for safety reasons (i.e., has to be totally free of any voltage potential to prevent injuries to people or equipment). When such a requirement arises, the relay must turn off, even if the relay rack has malfunctioned. In order to accomplish this, the relay rack must work in harmony with interlock and/or emergency stop contacts. Controlling solid state relays over electrical isolated Ethernet enables this control.

Programming

PLC/PC: PLCs are programmed using either one of the languages specified in IEC61131–3 (ladder logic, instruction list, etc.) or some proprietary vendor language, whereas PC-based controls can use programming languages such as C/C++/.NET. These languages offer unparalleled flexibility and easy integration.

Cost difference

For some applications, the difference in cost between a PLC and a PC solution may be quite significant, depending on requirements for performance, expandability, fab environment, and development work. When the application requires the control system to fulfill demanding calculations, handle complex network loads and process a lot of data, the PC-based solution will most likely be the best choice even though the initial cost of such a system might be higher. The advantage is that it provides a very powerful solution for which the cost increases only incrementally when more performance and functionality are required. Although basic PLCs generally start at a lower initial cost, they can quickly become more expensive than a PC when higher performance is needed.

PC controllers continue to advance dramatically in terms of power and capacity, as well as robustness. This makes them ideal products for integration into today’s increasingly complex manufacturing lines and workstations with their high demands for process and control capability, data collection and analysis, and complex software OS and user-friendly GUIs. One example is the Sensoray 626 PCI, that is an integral part of the abovementioned OEM’s glass product visual inspection systems. This higher level of control increases efficiency and reduces costs by allowing the users to configure only those functions they need on a modular platform, for example. To reduce capital expenditures while maintaining flexibility, the manufacturer can add additional inspection functions on the existing platform as the need arises. Such configurability and expandability is possible with the capacity provided by the PCI module. Product inspection parameters can be pre-programmed for easy recall, thereby reducing downtime for job changes. The 626 combines several popular interface functions on a half-size card. It has six versatile 24-bit counters that support incremental encoders as well as single-clock sources, 48 bidirectional digital I/Os (40 with edge detection), sixteen differential analog inputs, four analog outputs, and a watchdog timer.

Enabling technology

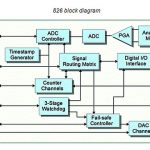

The 626 PC controller has provided expanded capabilities for the multi-functional inspection systems, but the new model 826 has enabled the launch of a technology advantage for the OEM’s flagship inspection system line due to the added capabilities of this next-generation module. The Sensoray 826 is a versatile analog and digital I/O system on a dense PCI Express board. It features 48 digital I/Os with edge detection, sixteen 16-bit analog inputs, eight 16-bit analog outputs, six 32-bit counter channels, a watchdog timer with fail-safe controller, and a signal router. The high performance, compact size, and abundant resources make it ideally suited for a wide range of measurement and control applications in many industries, including other functions especially important such as tracking and process verification, including trends of metered values.

The technology advantage, made possible by the greater capabilities, is software-based, but goes beyond software to actually constitute a ‘platform’. The company’s latest evolution in inspection technologies, expected to be the foundation for current and future system improvements, offering better lighting, higher resolution optics, faster and more powerful processors, advanced inspection algorithms and a simplified, intuitive user interface.

Conclusion

Both the PLC and PC-basedsystems have the ability to control a multitude of devices using familiar industrial communication networks and modern Ethernet-based solutions. However, the PC instrumentation is equipped with a more open and flexible array of interfaces that provides access to more off-the-shelf devices to handle tasks that a PLC could not usually handle. The PC system is better suited for complex control tasks and particularly for advanced processes requiring considerable memory. Robust and reliable, they excel especially in applications where a PLC would have limited storage and processing capabilities.

Share: