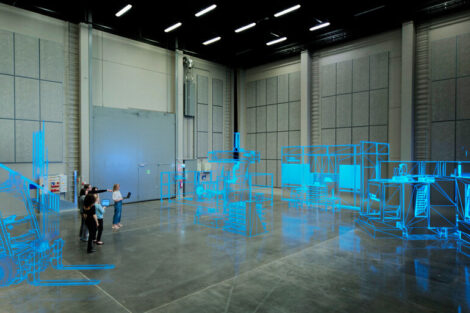

Technical cleanliness has become a quality criterion in the automotive industry and the associated supply sector. The evaluation and analysis of “residual dirt” is the key procedure here. For more than 10 years, dhs Solution has been a system supplier of software and hardware for standards-compliant residual dirt analysis.

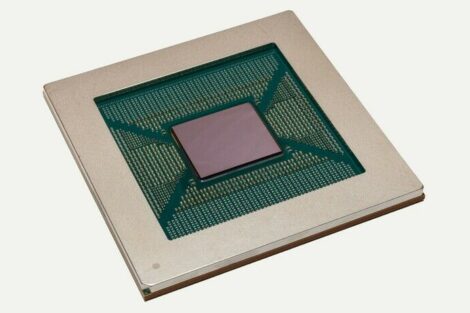

The company has recently introduced the newly developed version of a residual dirt analysis software with a user-friendly interface structured according to specific areas. As far as hardware is concerned, a sensor technology is offered for image capture with the option of scanning a number of filters in one procedure.

“Software is a living product. Its primary purpose is to provide accurate data, improve processes and reduce costs while helping to organize processes efficiently. By reworking the user and operating interface, we have made it possible to structure the various measuring and analysis options according to specific areas. The user is automatically guided through the menu in order to obtain their result. Processes during measurements have been improved and our software is now even more efficient,” said CEO, Christian Dietermann.

The Cleanalyzer software supports all external devices (camera, microscope, control systems, scanner):

- Intuitive, user-oriented interface features step-by-step guidance and is structured according to specific areas

- Test data can be collected, processed and documented quicker

- Touchscreen operation

- Detailed information regarding: type of contamination, number of particles, size distribution of the particles, properties of the particles

- Optical performance

- Data management due to automated results

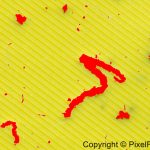

In combination with the newly integrated camera sensor for image capture, the image quality, scanning speed and data transmission are now even better.

The 6x insert plate for the Cleanalyzer Scan allows 6 filters to be evaluated in a single procedure. As a result, the particle load of components or particle traps for hall monitoring can be quickly analyzed. It is retrofittable and easy to mount.