High-reliability wire bonding has historically required the addition of a security bond over the stitch—or second bond—of each ball bonded wire. While this method does create a much higher reliability wire bond, it can at times lead to yield and other issues. It also requires forward bonding the wire every time.

Palomar Technologies, Erlangen (Germany)

If the package you are forward bonding to offers less than favorable conditions, you may be forced to use slightly higher than normal bond functions (higher force and/or ultrasonic power) to ensure that the second bond sticks. You then come back to that second bond and place the security bond over the heel of the wire resulting with a reliability wire. That slight over bonding process can sometimes lead to a lifted stitch you may or may not be able to rework, depending on your packaging requirements.

Use of Auxiliary Wires

Whether the need is due to poorly bondable materials, non-flat bonding surfaces, odd packaging situations, or just the need for high reliability; the integrity of a wire bond interconnect can usually be greatly improved through the proper use of auxiliary wires. Auxiliary wires are defined as security wires, security bumps, or stand-off stitch. A security wire has been the traditional asset for several decades; however, this is often replaced by security bumps which require a smaller second bond termination area. Further, stand-off stitch has many more applications and also has many side benefits that could be incorporated into a circuit design for better wire strength properties, fewer interconnects, and lower loops. Stand-off stitch bonding involves the placement of a ball bump at one end of the wire interconnect, placing a wire with another ball at the other end of the interconnect and then stitching off the wire on the previous placed ball bump. This results in a near homogeneous stitch bond interconnect to the bump with an inherent improvement in stitch bond pull strength.

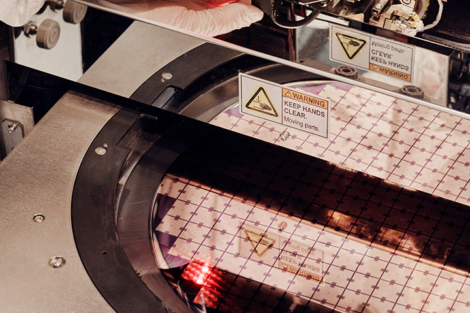

Automating the wire bonding process

The 8000 Wire Bonder / Ball (Stud) Bumper is capable of producing flat-topped ball bumps and bond normal ball-stitch wires in the same program with the same wire and same capillary, providing many options and flexibility in microelectronic packaging. For example, the first bond of a ball-bonded wire is very easy to bond, and usually has a very high process capability on an IC or package. The second bond of a ball-bonded wire is more challenging—even with near perfect materials—and has a much lower process capability. On forward-bonded wires, the second bond is generally placed on less than optimal material conditions. The weak link of a ball-bonded wire is, therefore, the second bond as it is more difficult to bond and is usually bonded to poor materials compared to the first bond. Stand-off stitch bonding greatly strengthens forward-bonded wires, generating high-reliability wire bonds!

With the capability to mix ball bumps with normal wires, you can place a flat topped bump on the second bond location. The ball bonds well to even less-than-favorable materials. When you then forward bond (ball on IC) stitch on the stand-off bump, you end up with a ball on both ends of the wire. The second bond diffuses nearly effortlessly into the flat-topped bump. When done automatically, you see a slight reduction in overall throughput due to the addition of the stand-off bump, but the reliability of the first level interconnect dramatically increases. And reliability can be increase even further. When forward bonding, the bonder must “kick-back” the wire above the first bond so that it can form a consistent loop profile. This type of motion in itself does not cause a reduction in reliability, but it does if it is done just above the bond in the Heat Affected Zone (HAZ) above the first wire bond.

Two types of bonding

The 8000 Wire Bonder has the option of forward bonding or reverse bonding. Stand-off stitch bonding can be performed forward or reverse. When reverse bonding, you put the flat topped bump on the IC and then place the first bond of a normal ball-bonded wire on the package surface and stitch off on top of the flat-topped bump. This method generates two benefits: no work hardening of the wire during looping in the HAZ zone, and a low loop profile above the IC. In a sense, this method of bonding emulates wedge bonding as it creates very low loops. You can even bond to MIL-STD-883 standards from die to die. In either case, stand-off stitch bonding delivers measurable improvements in the strength of the resultant wire with the vast majority of destructive tests breaking mid-span of the wire. Nothing is better than mid-span breaks in any wire bonded interconnect—the ultra high-reliability wire bond.

Zusammenfassung

Der Goldraht-Ball-Bonder Modell 8000 basiert auf einem innovativen mechanischen Design, moderner Steuerungstechnik und ansprechendem Bedienerinterface über LCD. Das System ermöglicht die Erstellung von planaren Gold-Bumps auf Wafern in nur einem Arbeitsgang höchst zuverlässig. Der Bondkopf mit patentierter Z- und Dreh-Achse sorgt für hohe Wiederholgenauigkeit, die Software sorgt für kurze Setup-Zeiten.

La câbleuse à bille à fil d’or modèle 8000 repose sur un design mécanique innovant, une technique de commande moderne et une interface utilisateur par LCD séduisante. D’une extrême fiabilité, le système permet de réaliser des bossements de soudure d’or planaires sur des plaquettes en une seule opération. La tête de liaison avec axe Z et axe de rotation assure une reproductibilité élevée et le logiciel garantit des temps de mise en train réduits.

More about….

…Palomar Technologies, a former subsidiary of Hughes Aircraft, is the global leader of automated high-accuracy, large work area die attach and wire bond equipment and precision contract assembly services. Customers utilize the products, services and solutions from Palomar Technologies to meet their needs for optoelectronic packaging, complex hybrid assembly and micron-level component attachment.

Palomar Technologies Assembly Services, located in Carlsbad, CA, is the contract assembly, process development, test and prototyping division of Palomar Technologies. Assembly Services provides process expertise with high-precision die attach, wire bond and component placement services, offering its customers an alternative route to meet complex packaging needs without investing in capital equipment.

Share: