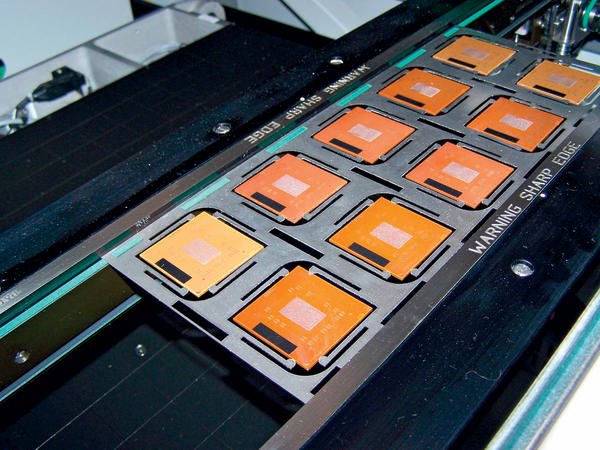

Building on the technology of its Virtual Panel Tooling (VPT) high throughput substrate imaging system, DEK has advanced this concept further and developed Virtual Panel Carrier (VPC). A substrate centering and carrier technology, it enables multiple component support and alignment during screen printing and all subsequent assembly processes. Traditional carrier technology used for processing small components generally requires individual component alignment and processing or the use of specialized and costly custom tooling to bring components into common alignment for printing. With all of the current systems, separate alignment processes for each component must be carried out at every process stage, thus resulting in less than ideal throughput and expense. The new technology alleviates these issues by enabling the components to be aligned once in the VPC for screen printing. Once this alignment occurs, no further adjustments are required for any of the subsequent assembly processes. “The design of VPC is quite extraordinary,” explains Neil MacRaild, DEK Americas General Manager. “With equal force being applied to each side of the substrate or device, centering is consistent with no chance for even slight misregistration. Plus, the system utilizes VPC’s global fiducials instead of individual component fiducials, which simplifies all stages of assembly and dramatically improves UPH.”

Through a design that consists of a base carrier with a low-maintenance consumable foil, the carrier provides the stability, centering and alignment capabilities required to process multiple substrates or components in a single panel, improving throughput. Parts are placed in the carrier either manually or loaded with a placement system. Substrates are held in the carrier via a patented 4-sided tensioning mechanism and then aligned within the carrier using an innovative centering system. Parts are referenced using two global fiducials – as opposed to individual component fiducials – thus enabling the easy transfer of VPC throughout all assembly processes. The system is also scalable, allowing manufacturers to adjust component quantity for individual processing requirements.

EPP Europe 429

Share: