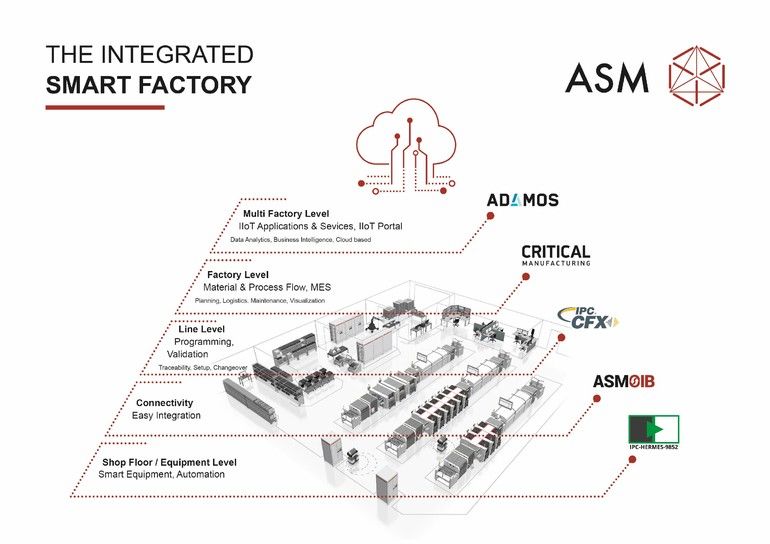

ASM wants to be the electronics industry‘s digital transformation partner who serves its customers with powerful production line solutions as well as with open protocols and solutions for total data and process integration on all levels of their manufacturing operations. The company’s skills range from seamlessly tracking each circuit board on its path through SMT lines via the IPC Hermes-9852 standard, to communicating process data via interfaces like ASM OIB or IPC CFX, to MES solutions from Critical Manufacturing and multi-plant integration via the Adamos IIoT and cloud platform.

“Outstanding equipment continues to be the foundation of any efficient electronics factory. But data will also play a critical role. Only someone who can provide reliable data in real time and irrespective of time, place and device will manage to be flexible and competitive in the future. Connectivity and data integration in manufacturing are complex tasks that require strategic partnerships between electronics manufacturers and digital transformation experts,” says Fuyan Yang, SMT Solutions Marketing Manager.

Open standards

The company has started several major initiatives in recent years to push the standardization of data protocols in the electronics industry. One result is the open Hermes standard, which ASM developed in cooperation with a group of international equipment makers as the successor to the obsolete SMEMA protocol. Based on modern standards like TCP/IP and XML and being recognized officially as IPC Hermes-9852, the standard can communicate board-related information between all kinds of machines from many different manufacturers. It makes it possible to seamlessly track each PCB through the SMT line with a single reading device. This makes it easy for electronics manufacturers to add new line components.

With ASM OIB, the company has also offered for many years a high-performance bidirectional interface that transmits process data from ASM machines to higher-level IT systems and receives control commands for the machines. For manufacturers who want to efficiently integrate a broad spectrum of machines from different makers, the company also supports the IPC CFX standard.

MES for the digital age

Last year, ASM invested in Critical Manufacturing and added another module for the smart integrated factory to its portfolio. Critical Manufacturing, a team of software and process integration experts, is known for developing and delivering an MES, which is considered to be one of the most modern on the market because it can reliably process and visualize the huge amounts of data that today‘s machines, robots, sensors, scanners and other systems generate. Critical Manufacturing’s MES also impresses with its detailed mapping of complete factories as ‘digital twins’, which allows users to not just monitor their processes and systems, but virtually optimize them. Another benefit: With Critical Manufacturing, the company has gained a team of software experts that has integrated machines from other makers into their MES for many years.

Secure cloud solution for manufacturing companies

Companies that want to integrate data from multiple locations with maximum efficiency prefer cloud-based solutions – if they meet their very high requirements regarding reliability, availability, and data security. To meet this demand, ASM has teamed up with DMG Mori, Rittal, Zeiss and other leading international equipment makers to establish the Adamos IIoT and cloud platform. Electronics manufacturers will be able to use this platform to integrate processes and data from many different locations and set up data communication with suppliers, partners and customers easily and flexibly.