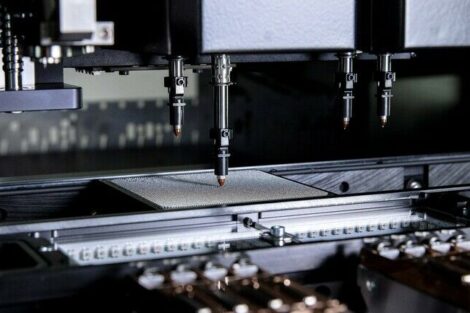

Soldering of complex SMD PCBs and new housing technologies require an exact controlled soldering process. The RO300FC from Essemtec is a full convection reflow oven that allows fast and homogenous heating, as well as high-temperature soldering of sensitive electronics. The integrated convection technology offers an innovative and efficient way of heating – with a vertical hot air stream that evenly heats the complete PCB. Both standard and lead-free pastes can be used.

The reflow oven now features RO-Control software for increased process simulation and control. The software combines all the important functions for the process evaluation and process control for reflow ovens and offers many of the same features as thermal profilers, but for less than half the price. Also, because the software is within the oven, the company is able to offer users an industry first.

The high air volume of the oven guarantees equal heating rates in all the components and the substrate, which leads to a minimum Delta-T and reportedly guarantees a perfect soldering process at every location on the PCB. This 80” long oven offers many of the same options – including chain conveyor for double-sided boards, computer control and an N2 option – as those available on ovens that are three to four times more expensive.

The temperature of the pre-heat and the peak zones along with the conveyor speed are programmable to obtain the required soldering profile. Measuring the zone temperatures directly in the convection airflow guarantees reproducible results with lowest Delta-T values (± 2 °C). Different profiles for solder and glue are already integrated in the microprocessor control. The oven provides a significant amount of capability at a small footprint. It can be used for prototypes, small batches and production runs up to 700 boards in an eight-hour shift.

The software enables the simulation of soldering profiles at different settings and the comparison with a solder paste library. The number of profiles managed with the software is unlimited. The software also controls and supervises the reflow oven, ensuring a safe operation. A saved parameter set can be selected from the profile library and can be transmitted to the reflow oven. The software steers and supervises the oven, and the actual status is displayed on the screen. Additionally, the paste editor allows the design and save profile references for different solder pastes. These references can be used by the profile simulator for comparison. The software also has the capability to save the process changeover to a lead-free process.

The reflow oven with RO-Control software is built in Switzerland. A five-year warranty on heaters and blowers is being granted. The oven offers simple and straightforward maintainability/reparability with the ability to completely remove each zone and clean them individually, along with full access to the electrical and electronics through drawers in the front of the oven.

Environmental factors are key and include low power consumption and low noise levels. The reflow oven is delivered complete with 20 preset profiles for production tasks and materials. For process specialists, the oven control offers additional memory for customized temperature settings and optional PC control with built-in oven profiling software. It is easy to use and can process even difficult lead-free pastes without extensive setup time.

EPP Europe 419

Share: