Medium-sized companies are the ones coming up with the real innovations – a fact confirmed by studies such as the one published in 2006 by the KfW (Kreditanstalt für Wiederaufbau). The latest impressive example of this phenomenon comes from EPM Handels AG in Geroldswil near Zurich, Switzerland, which has just launched a selective soldering machine under the name of Selecta – the CIG 400 Selecta Highspeed TMS. Once again, the company has gone its own way when developing this machine, including gaining a soldering patent.

EPM has been designing and building wave soldering machines for over 30 years, during which time – particularly after the takeover of the company by its former CEO and owner Hans Isler in 1990 – it has grown to become one of the world’s ten largest producers of wave soldering machines. Many people appreciated some time ago that the team has an intimate knowledge of their market. In view of this, they may be wondering why the company has chosen this particular time to launch the new Selecta machine onto a highly competitive selective soldering machine market. “It has always made sense to first examine the market calmly rather than to put a machine on the market in haste,” says owner and CEO Roland M. Hatebur. “We have been watching the situation patiently and have discovered which soldering processes and technologies our customers want and which ones they would rather do without.” Not many people realize that the company has been working with selective soldering technology for over 10 years (with the partial soldering machine (PSM) being the first EPM product of this type), during which time the company has gained extensive metallurgical experience in this field. “We shouldn’t forget that hardly any other electronics production technology has progressed as rapidly in recent years as selective soldering. Today, we have a highly advanced technology that is mature in every respect and which offers users everything they could ask for.”

Selective soldering with a wave soldering machine?

Sales manager Oliver Kägi, who spends about 90 percent of his time on location with customers and partners, confirms that the company is sensitive to the needs of its customers as far as selective soldering machines are concerned: “Quite a number of our customers are using our wave soldering machines with masks in a variety of sizes and shapes to carry out selective soldering, and to a certain extent, this method offers some of the functionality of the selective technology.” However, substituting a wave soldering machine for a selective soldering machine is not always successful or advisable. “Depending on the board, masks can be nearly 1 cm thick,” says Kägi. The problem quickly becomes clear. “The thicker the mask, the more difficult it is to get the board to the right temperature. And the larger the surface covered by the mask, the slower the soldering process becomes. Applying the flux becomes more difficult and preheating takes longer. Indeed, the entire process can become very complicated.” Kägi also warns against other knock-on effects. “Firstly, the additional costs are not inconsiderable. You can reckon on 300 to 400 euros per mask. And if you, as a manufacturer, have 30 or 40 different masks and have to replace them because they start showing signs of wear after a specific number of soldering operations, that can easily end up costing you a great deal of money.” By comparison, you would pay no more than around 1,000 euros for a set of tools per board for the selective machine – a price difference that is definitely worthwhile.

Kägi admits that it is common practice to solder selectively with wave soldering machines using masks to partially cover the board. But the question is, when, or in other words: How much masking, what thickness and size of mask is acceptable before you need to seriously consider switching from a wave soldering to a selective soldering system? “There isn’t a checklist that tells you whether wave soldering or selective soldering is the better choice for a particular job. Component layout is key to the choice of machine. The fewer high power components on the board, the more suitable it is for selective soldering,” says Kägi.

A host of new features

Compared to wave soldering machines, selective soldering machines use less energy and take up less space. They also offer tremendous savings on flux, solder and nitrogen. The Selecta also offers numerous additional benefits. For example, tools can be changed extremely quickly. Without shutting down the system, one can prepare the nozzles required on the board for the next job right next to the machine and fit them in less than 10 minutes. Flux is applied with the aid of a piezo jet fluxer – with a valve positioned with pinpoint accuracy applying the flux to precisely the right spot. The preheating, which is achieved using up to three different heating cassettes, is also very user friendly. Preheating (up to 125 to 135 degrees) takes place more slowly, so avoiding thermal shocks that could damage the material. This is achieved via pyrometer temperature control, a technology that makes its debut on this machine and that improves soldering results and cuts down on rejects. The pyrometer monitors whether the specified preheat temperature has been reached on the underside of the PCB. If not, heating continues and soldering does not take place until the prescribed temperature is reached. If this does not happen, the flux is not activated and no soldering takes place at all. The solder is conveyed to the board at an optimum temperature of between 250 and 265 degrees and not, as with most selective machines, at up to 310 degrees. Once again, the benefits are clear because working at this moderate temperature makes board delamination (splitting as a result of being subjected to excessive temperatures) impossible.

Applied for a patent

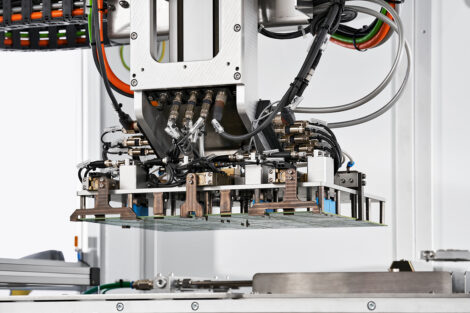

The selective soldering machine includes a special patent-applied-for soldering technology. “Unlike the dip soldering process, the nozzles on the Selecta remain in the same position throughout the soldering process. Pumps are used to transport the solder to the flues, where it is covered with nitrogen,” says Hatebur, explaining his new patent. Directly after soldering, the gripper unit holding the PCB makes a swivelling movement to ensure optimum peel-off of the solder flow before it places the board on the exit belt.

Camera monitors everything

Another innovative feature is the optional camera, which can check whether boards are sufficiently fluxed and also that there is always plenty of flux available. Nothing escapes its electronic eye – it knows if the nozzles are filled with solder and whether there is dross formation on the solder wave. There are two reasons why this is so very important, as Hatebur explains: “Since with selective soldering you normally have no way of checking directly whether a soldering process has completed successfully, you have to assume that it has. You rely on the solder wave to control the process. Only by ensuring that there is flux on the pins and on the board and that the flues are filled with solder and free of dross, can you be sure that the flux is at the right temperature and that the soldering process will complete successfully and without defects.” The second reason for employing a camera is equally as important, says Hatebur: “Manufacturing today is no longer satisfied with failure rates of one in a million. Companies are looking for “zero defects”, or 100 percent fault-free production. The Selecta’s video monitoring can help achieve this difficult production goal.”

Conclusion

When asked what he likes most about the machine and what its most distinctive features are, Kägi doesn’t deliberate long: “Its speed. This is one fast machine. It is quick to set up, tools can be prepared in no time, and best of all, it solders really fast, too. While other selective machines can take four minutes to solder a board, the Selecta solders four boards, or the equivalent, in just one minute. When you convert this soldering performance into productivity, the original investment in the machine can pay for itself within a very short time.”

EPP EUROPE 426

Zusammenfassung

Das Unternehmen, das bisher Wellen-Lötmaschinen produzierte, hat jetzt eine Selektiv-Lötanlage auf den Markt gebracht. Diese Anlage zeichnet sich durch ihre Schnelligkeit aus: Sie ist schnell eingerichtet, sie lötet mit einer schnellen Taktzeit und sie fertigt vier Platinen in einer Minute.

Cette entreprise, qui produisait jusqu’à présent des machine de brasage à la vague, a lancé sur le marché une installation de brasage sélectif. Cette installation se démarque par sa vitesse : son réglage est rapide, elle atteint une cadence de brasage élevée et produit quatre plaintes en une minute.

L’azienda, che fino ad oggi ha prodotto macchine per la saldatura ad onda, ha introdotto sul mercato un impianto di saldatura selettivo. L’impianto è caratterizzato da una grande velocità: viene predisposto rapidamente, salda con un ritmo elevato e produce quattro schede al minuto.

Share: