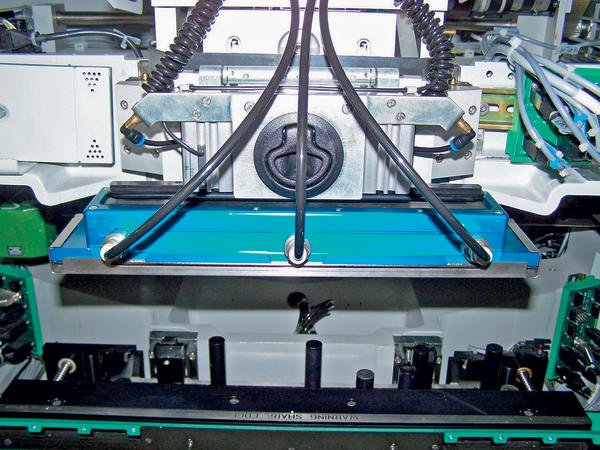

The M3i from DEK is a process-enabling system that provides turnkey materials management and printing capabilities heretofore unavailable, enabling high volume production of products that would otherwise not be manufacturable at high UPH. An automatic system comprised scalable materials management cartridges, a ProFlow enclosed head deposition system and a high accuracy Europa printing platform, the system offers superior programmable ratio mix control and imaging of a variety of materials. The materials are preloaded into precision, climate controlled cartridges and, through automated transfer, are fed into a specially designed enclosed head deposition system on-board a Europa printing platform. From here, the materials are accurately and precisely imaged onto the desired substrate or device.

“There are many, many applications that will benefit from DEK’s M3i technology,” states Neil MacRaild, DEK Americas General Manager. “Right now, for example, we are working with a leading semiconductor firm on an encapsulation application and, frankly, producing this product in high volume would not be possible without the M3i system. The possibilities for enabling new processes are endless.” The versatility of the system allows for materials to be stored in the cartridges at low temperature and then heated within the enclosed print head when elevated materials temperatures or melting processes are required. With the ability to control a variety of materials conditions – from temperature to metering to mix ratios – for unlimited volumes of material, the new system is an enabling technology for high-volume production environments where efficient materials management is essential.

It is completely scalable and can be used for numerous applications including, but not limited to: Underfill, encapsulation, solar cell and fuel cell imaging and many other packaging processes. As the system operates in real- time and is fully automated and programmable, throughput is vastly improved, errors introduced by operator intervention are eliminated, waste is reduced and significant cost savings are realized.

EPP Europe 441

Share: