DEK has developed a mass imaging solution that delivers higher throughput, high levels of accuracy and streamlined, flexible processing capability.

The company’s SinguLign enables the high accuracy mass imaging of multiple materials such as solder paste, solder spheres, flux and adhesive onto singulated substrates or components directly from the carrier, allowing the accurate processing of known good parts down to 20 mm in size.

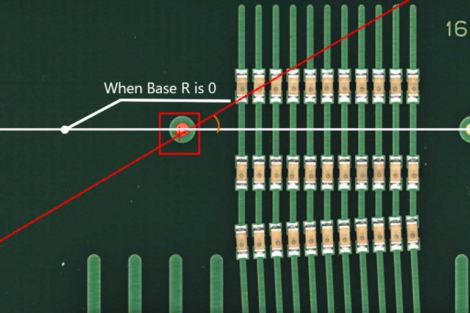

Through the use of a highly-accurate printing platform, specialized tooling, a carrier and a miniaturized print or ball placement head, repeatable and precise deposits can be applied to parts individually. The unique tooling and parts handling mechanisms allow for maximum print support and enable very high-speed processing times for individual parts – as little as 20 seconds for ball placement and much less for other print processes.

SinguLign delivers increased accuracy through the ability to align to substrate features – and not package edges. It enables ultra fine pitch imaging, providing yield improvement driven by the capability to process only known good parts, and supports multiple processes, depositing paste, flux, solder spheres or adhesive.

EPP EUROPE 442

Share: