Due to the ever-increasing demand for quality and reproducibility of the entire manufacturing process, today it is no longer acceptable to manually solder the conventional component remaining after the reflow process into place and – with the PowerSelective from SEHO – it is also no longer necessary. The machine offers all in one: highest flexibility, absolutely reproducible results, high soldering quality even with demanding assemblies, low capital expenditure and the possibility to be upgraded step by step at a later date to suit subsequent production developments.

It is provided with either a batch conveyor system or an in-line conveyor system to be integrated into a fully automated production line and can handle assemblies up to 500 x 500 mm. The machine may be equipped with a mini-wave soldering unit and a dip soldering unit, thus covering both processes with only one machine at simultaneously small footprint. To meet subsequent throughput requirements in the production, the machine may be extended with separate fluxer and / or preheat modules which will be installed in front of it. This reduces the cycle time remarkably.

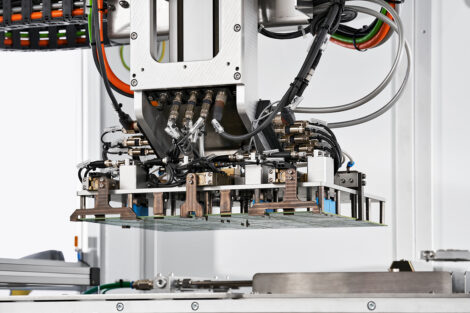

Flexibility is also given in the handling of the assemblies. Both, bare boards as well as assemblies in carriers can be processed with the soldering machine, whose ‚heart‘ is a highly precise portal axis system. The two x- and y-axis with servo-drive ensure a reliable positioning of the assemblies and work with a repeatability of ± 0.1 mm. Precise and constant process conditions, without any influence on the cycle time, are ensured with a spray monitoring system for the micro dropjet fluxer and a permanent touchless wave height control.

The teaching of the solder joints is particularly easy. A camera is used to identify the solder joints and read their position into the software. The software then automatically recommends default values for, for example, solder direction and soldering angle, dwell time and soldering speed. In case of a wide spectrum of assemblies there is an offline teach program available which leads you within only 10 steps to your soldering profile.

EPP Europe 416

Share: