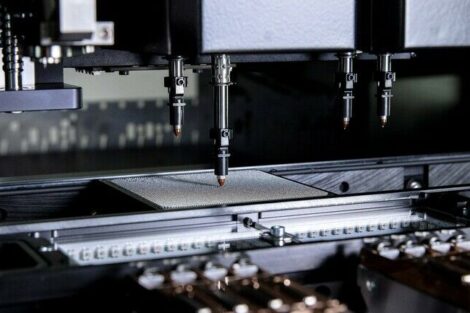

Pyramax 100 from BTU Europe is offered as an 8-zone air (100 A) or low consumption nitrogen (100 N) solution, both providing repeatable process control to ease the transition to lead-free. With a flexible platform configuration, the company’s exclusive closed loop convection control has been built into the forced impingement convection oven, with side-to-side air/gas recirculation to enhance temperature uniformity and guarantee process repeatability from system to system and site to site. With a maximum temperature of 350 °C, it provides excellent convection efficiency to reduce zone temperature set points and offers maximum flexibility in process control. The reflow oven’s water cooling system features closed loop cooling control for variable cooling rates and increased process control, with a sliding heat exchanger assembly to enable easy access for maintenance. The cost saving patented Flux Management System traps flux from the process chamber to prevent it from settling within the oven, resulting in valuable increased uptime. The reflow oven also provides multiple extraction locations to maximize overall efficiency of the system and an easy to access filtration and trap. Together with its ‘on the fly’ maintenance, these features combine in demonstrating an oven which offers very low cost of ownership.

Bundled specifications include a conveyor speed of 254 to 1524 mm/min (10 to 60 in/min) with a 50 mm to 457 mm (2 to 18 in) width. 8 top / 8 bottom heat zones with a heated length of 2540 mm (100 ”). 1 top cooling zone and optional bottom zone in the air option, with 1 or 2 top and 1 or 2 optional bottom in the nitrogen gas solution. The system has a footprint of 4648 mm (183 ”), 1524 mm (60 ”) in height and width, with a voltage range of 208 to 480 VAC. While bundled features also include Wincon Control software, Smart Product Tracking, belt and rail conveyors with fine mesh belts, high power heaters, retractable center support, automatic wafer handling/width adjustment and gas sampling together with dynamic gas idle.

EPP Europe 425

Share: