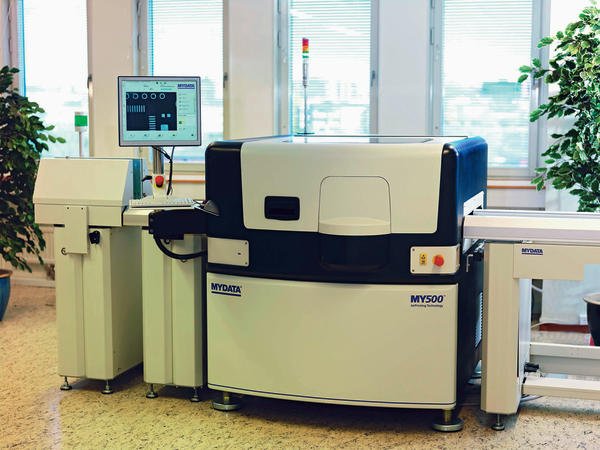

With complete off-line preparation, the second generation of the MY500 from Mydata can go from one production run to another in no time at all. The solder paste jet printer gives PCB designers more freedom to explore more PCB layouts than ever before with jet printing technology that provides more precise control over solder paste deposits. This allows larger components to be placed much closer to smaller ones, so the surface space can be maximized on every PCB.

“The MY500 gives you better process control, to increase accuracy and quality”, says Göran Persson, Mydata Product Manager. “The off-line programming allows setups and changeovers to be accomplished in seconds, so every production run can be started and completed as efficiently as possible. This will give users of the MY500 a clear competitive advantage and the ability to serve their customers with a very fast response time. The MY500 will also free up resources, leaving operators with more time for other responsibilities”. Göran Persson continues: “With the MY500 you can make adjustments on-the-spot, in three dimensions. The system features an easy-to-use two-dimensional inspection and repair functionality, so you can be sure to get exactly the result you expect.”

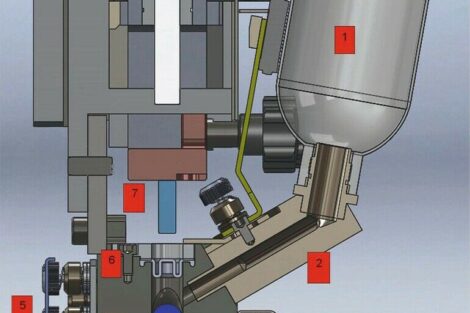

To maximize uptime during every production run, the machine’s paste syringe and ejection technology features the ease and speed of “snap-to-machine” loading. This allows to quickly refill paste when needed or switch from lead to lead-free solder paste in seconds.

EPP Europe 420

Share: