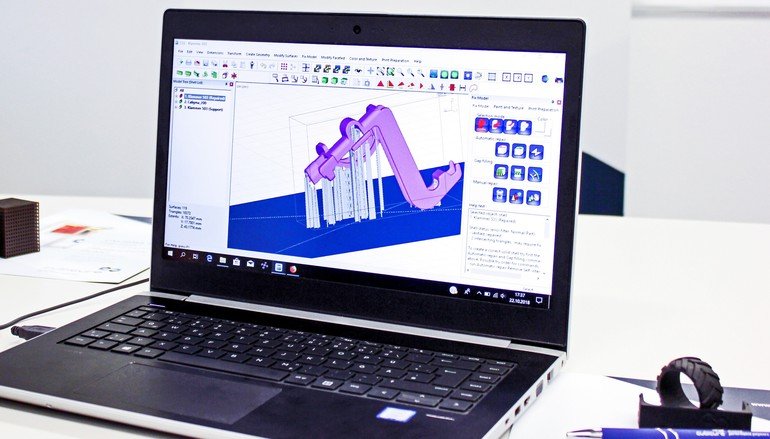

Cubicure has recently developed its platform-independent software solution for data preparation for additive manufacturing. CSS (Cubicure Support & Slice) software is a comprehensive tool for editing STL-files, generating support geometries and layer-slicing for 3D printers.

With this software, it is now possible to generate, edit and repair 3D models for various additive manufacturing processes as well as to export layer information for the actual 3D-printing process in an easy and reliable way. A user-friendly GUI and an intuitive import function of several surface models as well as data conversion tools facilitate the entry into the software. CSS offers comprehensive features and opportunities, for example manual or automatic generation of support geometries for additive manufacturing processes.

Model modification: A simple task with CSS

Quick operations, such as rotate, scale or mirror, allow models to be changed or multiplied in an arbitrary way. Clever part positioning can reduce the amount of raw material needed and process throughput can be optimized. CSS offers an additional feature, by hollowing parts faster building cycles and additional material savings can be achieved. Generating 2D drawings of the actual building envelope enables model identification and manufacturing documentation. “With this software solution, Cubicure offers another important product for the additive manufacturing value chain”, said Dr. Robert Gmeiner, CEO.

Optimized for hot lithography

CSS as a software solution is applicable for stereolithography based AMTs (SLA, hot lithography, DLP) as well as for powder-based systems. Especially for the company’s hot lithography technology predefined parameter settings allow a fast and optimized preparation of printing jobs for Cubicure’s 3D-printing machine Caligma 200. CSS was developed by the company in collaboration with graphic software provider DeskArtes and is based on 3Data Expert.