Smart power switches are highly integrated components for automotive and industrial applications. One major field of activity of the KAI – Kompetenzzentrum Automobil- und Industrie- Elektronik GmbH covers test and measurement of smart power switches and research on their reliability. This paper deals with the development of an automated test system for the characterization of smart power devices [1], [2]. As the system is intended to become a basic platform for various measurement tasks, the main focus has been on modularity and extensibility of both hardware and software. The measurement system is based on a PXI system plus external measurement devices; therefore it can be seen as a hybrid measurement system. Its software is developed in NI LabVIEW.

The challenge was to develop an automated test system for the characterization of smart power switches. As the system is intended to become a basic platform for various measurement tasks, it has been mainly focused on modularity and extensibility of both hardware and software. The measurement system is based on a PXI system and external measurement devices. The flexibility in hardware is achieved by incorporating four PXI matrix switch modules and a PXI relay module. The flexibility in software is reached by consistent incorporation of state machine structures as well as the usage of functional global variables. Moreover, functional modules of the software were encapsulated in standardized wrapper modules having equal interfaces. The software is based on a general-purpose architecture which means that it is not tied to specific hardware, but can be easily adopted and extended for the incorporation of other devices and for fulfilling other functional purposes.

The main motivation for the development of the test system is that it should reduce costs. The asset cost of a production tester is about 300,000 euro whereas the hardware cost of the test system described here is about 50,000 euro, not including the development effort. Another reason why the new test system has been developed is its easy and flexible operation. No in-depth programming knowledge is required for creating new test sequences because the test sequence generation is based on generic experiment descriptions. Additionally, it incorporates a graphical user interface for manual test sequence generation and adaption.

Hardware overview

The test system is mainly based on a PXI system incorporating an embedded controller, an FPGA module, power supplies, measurement devices such as a voltmeter and multimeters, a function generator as well as switching matrix modules. In addition external devices, namely a power supply and an electronic load, are connected via GPIB or USB. Finally, a CompactRIO expansion chassis is connected to one of the digital IO ports of the FPGA module, providing protected digital and analog IOs. The FPGA module enables user-defined triggering, timing, and onboard decision making. Here, the main purpose of the FPGA module is to provide the start trigger for the measurements of the PXI devices as well as for the externally connected electronic load.

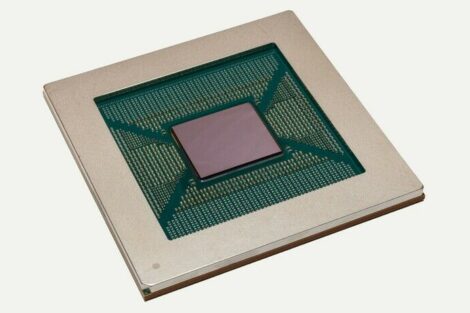

Device connectivity

Figure 1 shows a photograph of the interface board for the device under test (DUT). The in- and output terminals of the PXI measurement, signal generation and power supply devices are connected to the printed circuit board (PCB) on the left by BNC and 2 mm sockets. These IOs are connected to the switching matrices via a multicore connector (large silver connector on top of the picture). Using the matrices the IO channels can be routed to any desired terminal of the DUT which is connected by means of a substrate and an adapter PCB (the green PCB in the middle). The high current path of the DUT is supplied via power plugs (two green plugs on the right top). These connect the power supply as well as the electronic load via the PXI relay module to the DUT.

Software architecture

The software of the test system has been developed in NI LabVIEW. As the software should become the basis for several different test systems, the choice of software architecture plays a major role. Especially modularity and extensibility had to be well considered. The software architecture is shown in figure 2. The instruments, divided into the two device categories of PXI internal devices and externally connected (GPIB, USB) stand-alone devices, are depicted. Using the device-specific drivers – which can be provided as e.g. LabVIEW Libraries (LLBs) or application programming interfaces (APIs) – the instruments are encapsulated instrument modules which are implemented as functional global variables. Due to the encapsulation of the instrument drivers the system can interface PXI instruments as well as external devices and hides the different instrument categories from the upper software layers. In addition to those instrument modules, other functions are implemented in the same way. These functions serve for calculations on the measurement data, conditional decisions on the test sequence, loop functions for repeating subsections of a measurement sequence with altering settings, or for outputting acquired data to a file. On top of these modules and functions, the main engine takes control. This main engine is implemented as a so-called queued state machine. This means that its subsequent states are lined up in a queue prior to their execution. Such a sequence of states serves for the definition of a measurement task and can be created within the sequence editor user interface or can be generated out of generic experiment descriptions.

Modularity and extensibility

In order to achieve modularity, two major software design elements are frequently used, namely the “state machine” concept as well as the concept of “functional global variables.” Moreover, functional modules of the software were encapsulated in standardized wrapper modules with common interfaces. Instrument modules for controlling measurement devices usually have functions for device initialization, configuration of measurement and trigger settings, reading the measurement data as well as shutting down the device resource again.

Conclusion

Due to the test system’s modular and extensible architecture, it can be adapted and extended to various kinds of measurement tasks. In addition, it has the major advantages of being reasonably priced, quick and easy to configure compared to other test equipment previously used. The remarkable advantage of the described test system is that it can interpret generic experiment descriptions which are used for automated simulation as well as for production tester measurement. The test system does not only have a competitive advantage compared to complex tester equipment, but also compared to manually configured test and measurement circuitry because it rules out the variation of test results which is caused by the variation of the test circuitry and user interaction to a certain extent.

electronica, booth A1.317

EPP Europe 428

References and acknowledgment

This work was jointly funded by the Federal Ministry of Economics and Labour of the Republic of Austria (contract 98.362/0112-C1/ 10/2005 and the Carinthian Economic Promotion Fund (KWF) (contract 98.362/0112-C1/ 10/2005).

[1] W. Gallent, “KLAX – An Automated Laboratory Test System for the Characterization of Smart Power Switches”, Master Thesis, Fachhochschule Kärnten, Villach, 2007

[2] A. Pirker-Frühauf, W. Gallent, M. Kunze, and G. Pelz, “Acceleration of IC verification process using advanced flexible modular measurement systems and software architectures”, IEEE International Instrumentation and Measurement Technology Conference, Victoria, Vancouver Island, Canada, May 2008

zusammenfassung

Die Herausforderung bestand darin, ein automatisches Testsystem für die Charakterisierung von Smart Power Switches zu entwickeln. Da das System als Basisplattform für verschiedene Messaufgaben gedacht ist, ist es hauptsächlich auf die Modularität und Erweiterbarkeit von Messgeräten ausgerichtet.

Le défi consistait à développer un système de test automatique pour la caractérisation de commutateurs intelligents (smart power switches). Le système étant conçu comme une plate-forme de base pour diverses tâches de mesure, il est essentiellement axé sur la modularité et l’extensibilité des instruments de mesure.

La sfida era sviluppare un sistema di test automatico per la caratterizzazione dei commutatori Smart Power. Poiché il sistema funge da piattaforma di base per diverse misurazioni, è stata data particolare importanza alla modularità ed espandibilità degli apparecchi di misurazione.

Share: