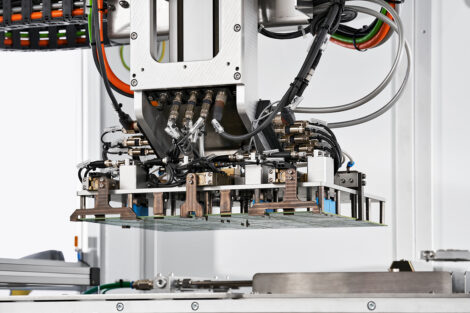

Selective soldering systems from ACE Production Technologies feature internal (integral) preheat capability that has been designed for large, high-mass assemblies which are a challenge for selective soldering, where process heat is applied only to the bottom side of the assembly. The ability to apply continuous, real-time top-side preheating during the selective soldering process is critical to achieving good soldering results when processing such assemblies. The preheating capability promotes the draw of the solder through the barrel to the top side of the board, enhancing the formation of solder fillets on the top side. The implementation of internal continuous preheat, during the selective soldering process, improves thermal distribution and solderability of difficult assemblies. All of the show machines will also include dual flux heads – one spray- and one drop-jet, a flexible feature added earlier this year.

Productronica, Stand A2.105

EPP Europe 454

Share: