As one of the largest technology service providers and electronics specialists in Germany, system provider TQ Group says it offers customers reliable solutions based on the latest manufacturing technology. The company is now further future-proofing its solutions by adding the newest 3D inspection systems for SMT production from Saki Corporation to its portfolio.

TQ-Group was founded in 1994 by Detlef Schneider and Rüdiger Stahl. Thanks to consistent growth and wise investments, the Group now comprises around 1,700 employees in 15 locations – 11 of which are in Germany. Its headquarters, located in Gut Delling in Seefeld, just West of Munich, currently house around 500 employees and comprise the Group’s strategic decision-making centre.

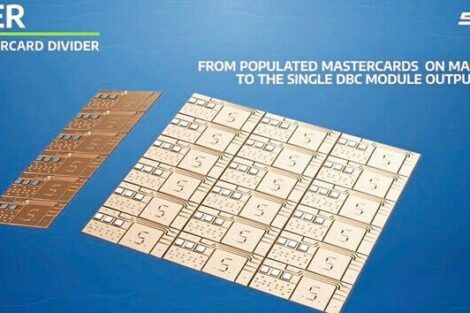

At €284 million for the financial year 2020/21, the annual turnover of the owner-managed business speaks for itself. The company’s German branches include sales, production and development departments to support specialist requirements, all broadly positioned in the Electronic Engineering Manufacturing Services (E²MS) space. Augmented by a comprehensive range of in-house products such as embedded modules, base boards and drive & automation solutions, products are developed and assembled on a customer-specific basis using a proven modular process to meet specific and unique requirements. The company says the use of this proprietary modular approach to provide services and solutions reduces development times and costs.

The ‘Inspection Systems’ project

“Due to increasing miniaturization and complexity, combined with very different surface mount device heights, our components were no longer 100% inspectable with conventional inspection systems,” explained Werner Bäumel, Head of Production at the Delling plant. “New inspection systems were absolutely necessary. In this respect, an effective solution had to be found that would allow us to continue to supply and guarantee perfect quality to our customers.”

Quality is ensured by continuous monitoring of SMT assembly processes: the only practical way to mitigate the costs and wasted time of repair and rework. Previous quality assurance procedures were designed for two-dimensional inspection operations but it was clear these were not sufficient to meet the requirements of the wide variety of assemblies being produced. “In addition, the Automatic Optical Inspection (AOI) systems at the end of each assembly line turned out to be a bottleneck over time,” pointed out Production Manager Markus Luschnig. “Through a process of careful and intensive market analysis and evaluation, we made the choice to invest in inspection systems from Saki at the end of 2020. It turned out to be a very good decision, as proven by the excellent experience we had during delivery, installation, training and commissioning – all of which were fast and without complications,” Luschnig explained.

The TQ-Group’s ‘Inspection Systems’ project was founded on the proposition that all SMT assembly lines within the company group should feature the same process equipment. This was to ensure company-wide consistency and a degree of redundancy for optimum flexibility between jobs and projects. “As a result, the task was more complex, as we had to find a system that could map and accommodate all the products and challenges across TQ’s plants,” Luschnig revealed.

At the Delling plant, for instance, high-mix low-volume batches of 1 to 2,000 boards are produced, whereas at the Durach plant, the number of units per batch is higher, meaning that fewer changeovers are required. One Solder Paste Inspection (SPI) system and one AOI machine were required in each of the three SMT assembly lines at the two locations. Now, one SPI and three AOI systems are inline at the Delling plant.

“About two years ago, we began to take a closer look at the equipment in the SMT areas of the group of companies and decided to replace old equipment,” said Luschnig, explaining the company’s technology strategy. “The last piece of our puzzle was to decide upon suitable inspection equipment. We knew that we needed to define what suited us best and would cover our varying requirements effectively because we don’t just look to assemble electronics, we need to manufacture a system. With these systems, we also have to accommodate a high level of customization, even with quite small batch sizes,” clarified Luschnig. “In addition, one of our big goals in the next five years is to make progress in terms of digitalization, for which we have created a strong foundation through the partnership with Saki, as these inspection systems offer the very best conditions for interfacing with artificial intelligence,” he added.

Technology with an eye on

the future

The Saki 3Di-LS2 automatic optical inspection systems plus side cameras with 18 µm resolution and SPI 3Di-LS2 with 12 µm resolution were chosen. The 3Di series uses state-of-the-art technologies to improve production efficiency and quality across the entire SMT line. The Japanese manufacturer’s innovative hardware and software technologies deliver precise measurements while inspecting at high speeds. Quantitative height measurement detects component size and position accuracy for a wide range of components.

Bäumel also identified further advantages of the 3D AOI systems in production: “Since using the new systems, our pseudo error rate has been reduced by up to 45 %, meaning that the operator has to recheck less often, so we have been able to cut our cycle time considerably. I think this is down to the software intelligence, which is very robust and reports only relevant results,” he explained. On the challenging issue of the wide range of component heights deployed across SMT assemblies, Bäumel gave an example: “Often, it’s necessary for the design to have extremely small components placed right next to very tall components on the board. With a 2D inspection system, it was difficult to inspect those smaller devices with confidence. But now, the third dimension of measurement provided by the 3D AOI process lets us see things that were previously not discernible. We can recognize process fluctuations and their cause very quickly, so today we can maintain the stability of our processes.”

Reports about the SPI system are also overwhelmingly positive. The 3D capability of the SPI system measures the shape, the volume and the position of printed solder paste deposits. Using closed-loop feedback control, the screen printer then constantly adjusts itself, resulting in extreme repeatability in terms of paste printing and far fewer errors at the end of the process. The SPI machine design includes a dual Y-axis drive and two servo motors with linear encoders to ensure high precision and repeatability as well as fast inspection speeds. By imaging and storing the entire PCB surface, warpage compensation and 3D viewing are enabled to support traceability requirements. Any image of the board or components can be retrieved and displayed later. With Gerber data, the same data can be used for both AOI and SPI with Saki’s Self-Programming Software. The common hardware and software design deployed in the 3D AOI and SPI product lines reduces training time and spare parts inventory holding, while simplifying maintenance and shortening lead times.

A win-win partnership

“It was the innovative power of the software that convinced us to make the investment in these Saki systems,” Bäumel emphasised. “Due to the high product variety, it’s vital to be able to create programs quickly, especially given that all manufactured assemblies are 100 % inspected.”

The initial contact was with Björn Lohse of Selecs at the end of 2020. In January 2021, the first AOI was taken offline, and work began on writing the programs in preparation for the inline process.

With up to 8,000 different types of assemblies produced each year, it is unsurprising that a Saki technician was on site for a fortnight to support the installation, including creating interfaces to communicate with the TQ MES system and undertaking equipment commissioning and user training. “After just one week, the system was ready for inline testing. In the event of any issues, the customer service team would connect to the machine remotely from Prague to sort everything out,” Bäumel said.

Jarda Neuhauser, Managing Director of Saki Europe, is also very pleased with the successful partnership. “I am delighted to have a strong company like TQ-Group as a partner. The installation here was smooth and very successful from both sides; an all-round effective and rewarding collaboration between the teams from both companies,” he said.

“Saki Corporation and TQ-Group are both leading technology companies that provide highly reliable solutions to their customers around the world,” Luschnig added. “We are confident that this synergy will add great value to our customers and benefit both companies. We are very much looking forward to further strengthening our strategic partnership with Saki Corporation.”

SMTconnect, Booth 4A.135

www.sakicorp.com/en/ | www.tq-group.com

Zusammenfassung Résumé Резюме

Systemanbieter produziert verlässliche Lösungen durch innovative 3D-Inspektionssysteme in der SMD-Fertigung und stellt sich so zukunftssicher für die nächsten Jahre auf.

Le fournisseur de systèmes produit des solutions fiables dans la fabrication de CMS grâce à des systèmes d‘inspection 3D innovants et garantit ainsi sa pérennité pour les années à venir.

Поставщик систем производит надежные решения с помощью инновационных систем 3D-инспекции в SMD-производстве и, таким образом, позиционирует себя как перспективное предприятие на ближайшие годы.