Today, UV-curing chip encapsulants have become an accepted standard in many areas of electronics production. Their short curing times turn these adhesives into a beneficial encapsulation solution in particular for high quantities in in-line production. Their typical application areas include the encapsulation of smart card chips. Though, once opaque materials are in demand or extreme mechanical loads arise, these products reach their limits. In such a case, the chips are often molded in a complex process, in other words they are coated in a kind of die casting procedure.

Rainer Dörfler & Andreas Siupka, Delo Industrial Adhesives, Windach (Germany)

Delo has developed new Dam&Fill encapsulants, the heat-curing adhesives are non-transparent, provide a very high level of mechanical protection and can be easily processed on existing encapsulation systems.

High requirements on smart cards

The smart card industry, also the use of adhesives presents enormous challenges. They have to safeguard the module function in production, during postal dispatch and in practice at the end user as classic chip card or as SIM card in the mobile phone. The chip and the contacts must be mechanically protected from pressure, bending stress and torsion. In addition, the sensitive silicon chips and gold wires must be sheltered from physical impacts and environmental influences such as humidity, coldness and heat. As a consequence of the multifaceted use, a great variety of requirements must be fulfilled.

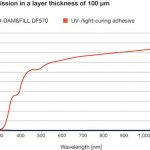

The new Dam&Fill adhesives have essential advantages for such requirements, especially in the safety area. The new developments became feasible by using a novel, thermal initiator that, so far, has enabled fast curing of UV-curing epoxy resins only. As the polymerization shrinkage during this type of curing process is comparably low, resins with a very tightly crosslinked network can be used without mechanically overloading the chip during curing. The high hardness of these resins gives a very high level of mechanical protection. The opportunity to opaquely encapsulate the chips without molding them in an expensive process is brand-new. This is important for chips that are sensitive to light or must be bent for safety reasons. Unlike UV-curing encapsulation materials, the new adhesives bring about complete opacity in the UV range and near IR range.

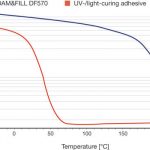

The new products can be processed and cured on existing chip encapsulation systems. Therefore, it is not necessary to purchase new special systems. The only precondition is that the systems are equipped with modern heating bars. The UV lamps integrated in these systems are not needed. The relatively low minimum curing temperature of 110° C and curing times of a few minutes open up manifold opportunities for further applications.

Demand on adhesives

The fulfillment of safety requirements is just as essential as the adhesives’ duty to safeguard the functioning of the chips at physical and thermal stress. What is especially important is that the chips are reliably protected from being manipulated or accessed without authorization. The protection of the chip patterns of light-sensitive storage modules is part of that. Due to their structure, these patterns may be damaged by light and must be protected by light-tight encapsulants.

On the other hand, the light sensitivity of the chips is utilized to protect them from unauthorized accesses. When trying to unveil the chip or to recognize its surface patterns, its functions are disrupted. In addition, certain safety requirements of the special Federal Information Processing Standard (FIPS) must be fulfilled. According to the standard’s provisions, high mechanical protection alone or in connection with optical protection must be guaranteed.

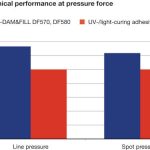

Country-specific requirements on a chip module or the protective encapsulant depend, for example, on the card readers used. In some ATMs, the contact pins are pressed to the contact surfaces with increased force during “reading” of the card. Accordingly, the encapsulation material used must provide a higher level of protection from line and spot pressure. The new heat-curing adhesive combination with Dam&Fill DF570/DF580 delivers a clearly better performance than conventional UV-curing products and therefore can fulfill the increased requirements. The adhesives’ higher level of protection becomes apparent when comparing the mechanical load values. The breaking loads the new encapsulants in load tests for smart card modules with spot or line pressure are 20 to 40 % higher than those of conventional materials and thus equal the values of molded packages.

Reliability increase through testing

In order to safeguard the protective function of the encapsulation compound, and therefore the functioning of the chip under all physical and mechanical loads during its lifecycle, comprehensive tests are conducted and all loads the connection will be subject to are simulated. Individual modules and complete modules were subjected to extreme stress. The specific tests included storage at temperatures up to 150° C for several hundred hours, storage at temperature changes and temperature shock and storage at elevated temperatures and humidity, as well as bending and torsional tests such as the 3-wheels test. The 3-wheels test allows conclusions on the loading capacity of the chip module when being inserted into the ATM. It turned out that the modules encapsulated with the new encapsulation compounds withstood the elevated load of 15 N for 150 cycles. Good UV-curing materials survive a maximum of 50 cycles under this load. The adhesives also passed all further qualification tests for smart card modules.

The new black adhesive can be used as an alternative to molding everywhere where classic UV-curing products cannot fulfill the requirements on mechanical strength and opacity, mainly in chips for smart card modules. But the new materials have also proven their efficiency as encapsulants for driver chips in display cards that impose very special requirements. In addition, it is possible to encapsulate biometric sensor chips and to solve microelectronic applications with high demands on component protection. The advantages of the new Dam&Fill adhesives are clear.

They give high mechanical strength and opacity, which has only been possible with molding so far. They can be processed on conventional encapsulation systems. Therefore, new investment in dispensing units or processing machines is not necessary and no cost-intensive tools or systems for molding must be purchased. What’s more, the Dam&Fill process is flexible as regards the encapsulation geometry so that small series can be produced in an economical way. In addition, the components can be exchanged quickly in production which leads to short tooling times.

Zusammenfassung

UV-härtende Chipvergussmassen haben sich in vielen Bereichen durchgesetzt. Sind optisch intransparente Materialien gefordert oder treten extreme mechanische Belastungen auf, kommen diese Produkte an ihre Grenzen. Aus diesem Grund hat Delo neue Dam&Fill Chipvergussmassen als innovative Lösung entwickelt.

Les masses de scellement durcissant aux UV se sont déjà établies comme standard dans de nombreux secteurs. Ces produits montrent toutefois leurs limites en rapport avec des matériaux non transparents ou des sollicitations mécaniques extrêmes. C’est pourquoi Delo a mis au point de nouvelles masses de remplissage Dam&Fill.

Share: