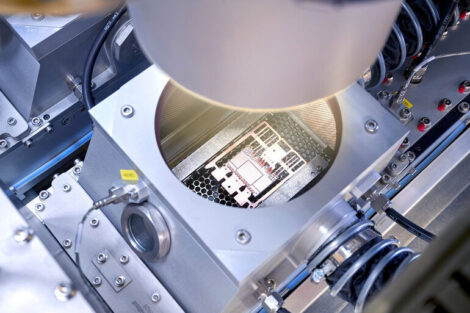

Vitronics Soltec has launched the next generation of advanced reflow soldering systems with the XPM3. This “ready for lead-free” system offers more efficient heat transfer through a proven high-mass heater design. It gives the user the ability to achieve higher lead-free product temperatures with lower gas temperature set points, without increasing convection velocity. Built upon the successful, battle-tested XPM Series platform, with more than 2,500 systems installed worldwide, the new reflow soldering system offers signature XPM reliability and repeatable performance in the new world of 3-shift, totally lead-free soldering. The system represents the next level in process control, which is essential to high-volume production of lead-free assemblies. Energy consumption is efficient, and user-set cooling gradients help the user realize maximum solder joint quality. The cooling system is easy to maintain, and is entirely closed-loop in function and design.

Optimized process control and an advanced patented Gas Recirculation System (GRS) allows the XPM3 to run product at higher conveyor speeds with better atmosphere control and lower nitrogen usage. The GRS serves to maintain a cleaner process and cleaner oven by removing flux volatiles, while at the same time maintaining heat transfer efficiency and atmosphere control. The system’s highly efficient nitrogen inerting system – reportedly the most efficient in the industry, with optional closed loop capability – ensures optimum soldering results at the lowest practical gas usage and cost.

The reflow soldering system uses the company’s advanced, user-friendly control software that maximizes the capabilities of the machine, with greater added functionality, flexibility, and capability. Additionally, it integrates a specialized Autoset closed loop profiling control package that delivers faster oven set up, process optimization, elimination of periodic profiling, and process traceability. It takes the “guess work” out of profiling for the operator, saving valuable time. Modular platform architecture with standardized interfaces allows users to benefit from future technology upgrades. Its improved XCS Conveyor System ensures safe, reliable transport of product with dual lane flexibility for high volume processing capability. Multiple board support systems are available.

EPP Europe 423

Share: