One of the leading Electronics Manufacturing Service providers in the UK and Ireland replaced an outdated surfactant cleaning application with a modern, fully automated, water-based process solution to match the highest customer requirements for the cleaning of high frequency (HF) populated electronic assemblies.

Johannes Karwey, Process Engineer, Zestron Europe

The company in this case study has experienced a tremendous amount of business growth as an Electronics Manufacturing Service provider in more than one decade. In the beginning, the company was solely focused on supplying customers in niche markets with suitable product solutions, whereas nowadays it is one of the leading providers in the UK and Ireland. The company’s current line of ser- vices consists of combining design for manufacture and dedicated prototype facilities with volume manufacturing, global sourcing, testing, system assembly, logistics and post warranty support.

The company’s customers operate in high end markets where the quality of the end product plays the most critical role. To ensure the highest product reliability over a lifespan of 10 years and more, the company had already installed an electronics assembly cleaning pro-cess in its early stages of production. Over the years, the customer base and with it also the product range increased. With these expanded application areas, demands on the existing cleaning process were also growing. Very soon, the company found itself in a situation where the ability to sufficiently clean the latest customer boards became an increasing issue. Therefore, it was decided to replace the existing cleaning application with a modern cleaning process.

Limitations of the conventional process

At the time, it was decided that a search for a new cleaning process was needed as the defluxing of the assembled boards was performed in a 4-chamber dip tank machine. The first stage equipped with ultrasonic transducers was filled with an alkaline surfactant-based cleaning agent. This cleaning stage was followed by a pre-rinse and a final rinse stage to remove any remaining flux as well as cleaning agent contamination. The final stage of the process was a hot air drying chamber.

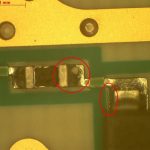

The main issue observed was the insufficient removal of solder ball formations on several boards, which were produced for high frequency applications. With the remaining solder balls on the boards, the cleanliness quality standards set by the company’s end customers could not be met. Despite several attempts to optimize the process, the cleaning results remained unchanged and dissatisfying. With these issues in mind, the company decided that a new cleaning process needed to be installed to replace the old surfactant application and defined the following requirements:

- Enable the complete removal of solder balls and flux residues on the HF assemblies to meet the customers’ requirements

- The new cleaning process should be fully automated to match the current and also future production throughput

- Provide easy handling for the operators, improve health and safety situation

The first steps – where to start?

The project was assigned to the company’s Quality & Process Engineering Manager. The task at hand was to specify and install new cleaning equipment that would meet the above mentioned main requirements. Additionally, he was to also identify and implement process improvement tools and techniques as well as maintain quality standards. Ultimately, the goal was to replace the existing PCB cleaning machine with a process that would be modern and easy to operate while providing superior cleaning results.

First, a user requirement specification matching the estimated future throughput was compiled, which included considerations for cycle time, flux types, cleanliness, board size and material consumption. As a second step, a study of the existing equipment market was conducted and various manufacturers were considered through visits to trade shows, workshops and distributor facilities. For the Quality & Process Engineering Manager, the market re-search made it apparent that a visit to Zestron’s Technical Center in Germany would provide him with the best starting point to take this project further. He said that the main advantages for him were to have the opportunity to get a comprehensive overview of different machines from leading industry suppliers, conduct cleaning trials with boards at hand and make comparisons, all within a matter of one to two days.

Comparative cleaning trials

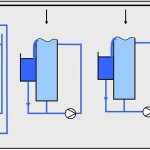

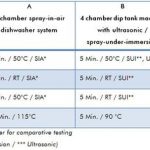

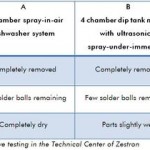

Upon arrival at the Technical Center, the Quality & Process Engineering Manager was supported by one of the process engineers. After analyzing the process requirements, he was introduced to different single and multi-chamber cleaning machines and agitation methods including spray-in-air, spray-under-immersion and ultrasonic systems. For the cleaning trials with the HF boards, the three cleaning systems one chamber spray-in-air (SIA) dishwasher system, the four chamber dip tank machine with both ultrasonic (US) and spray-under-immersion (SUI) agitation and the four chamber dip tank machine with spray-in-air (SIA) cleaning and spray-under-immersion (SUI) rinsing were finally selected. To allow for comparative testing, all cleaning trials in these three different pieces of equipment were conducted with a similar set of process parameters. The results of all cleaning trials were immediately assessed in accordance with the customer requirements.

The first piece of equipment, a one chamber dishwasher system (A) offers great advantages as it is a very compact cleaning solution with a small footprint and has a fully automated set-up, where all stages, cleaning, rinsing and drying, take place in one chamber. During the cleaning trials, flux residues could be completely removed with the dishwasher system. The machine also provided excellent drying characteristics although the time needed was by far the longest. However, the solder ball formations from the reflow process could not be completely removed from the HF boards. Thus, this cleaning machine was soon dismissed as a possible solution.

With the second cleaning machine, a four chamber dip tank system (B) with both ultrasonic and spray-under-immersion agitation, the Quality & Process Engineering Manager saw great possibilities in terms of cleaning quality and being able to meet even higher throughput requirements in the future. The system consists of 4 single tanks: cleaning stage, pre-rinse, final rinse and drying chamber. Due to the single tank set-up, multiple carriers with PCBAs can be processed simultaneously. Therefore, higher throughputs can be achieved compared to a single chamber equipment set-up. However, the cleaning trials brought to light that neither the ultrasonic nor the spray-under-immersion of this cleaning machine could completely remove the solder balls from the HF boards. Additionally, the drying results of the boards where not satisfactory. In turn, this potential solution was also dismissed.

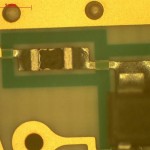

The third cleaning machine was a four chamber machine (C) with direct spray-in-air and spray-under-immersion agitation. Similar to the dip tank machine, the process consists of a cleaning stage, pre-rinse, final rinse and a drying stage. The main difference is that the cleaning stage is equipped with direct spray-in-air agitation while the pre-rinse and final rinse stages are equipped with spray-under-immersion agitation. With this fully automated system, a complete removal of flux residues as well as solder balls could be achieved. Additionally, the drying results in this machine were excellent due to an optimized air flow system.

The new cleaning process

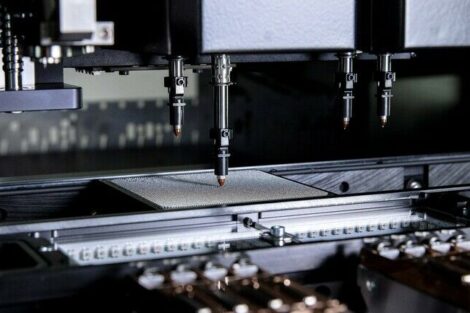

With the results clearly pointing towards the third option, the decision was finally made to purchase the four chamber cleaning machine with direct spray-in-air and spray-under-immersion agitation. Due to the extensive evaluation trials at the Technical Center in Germany, the machine could be installed and the process was set up without any issues. Since its installation 1.5 years ago, the machine has been running without any problems and continues to provide consistently excellent cleaning results. Apart from its superior cleaning ability, the machine also meets the other requirements set by the company, as it is fully automated to match higher production throughputs and ensures easy handling for the operator. The complete automation is achieved by a parallel transport system that can be controlled by the operator using an integrated touch-screen menu. It allows the operator to access all process steps and to individually set cleaning, rinsing and drying parameters, such as time and temperature.

For the cleaning process itself, all assemblies are fixed into carriers, which are automatically transported to the cleaning chamber. On both sides of the chamber, spray arms are mounted, which begin to rotate as soon as the cycle time starts because of the pump pressure. Due to the low rotation speed, the spray jet strikes the boards at a right angle, which also prevents any shadowing effect. Using 3.5 bar spray pressure, the system is able to completely remove all flux residues as well as the solder ball formations from the assemblies. For cleaning, the decision was made to use the water-based agent Vigon A 250, which provided the best cleaning results during the trials at the Technical Center. The cleaning stage is followed by two closed loop dip tank rinse stages with spray-under-immersion agitation for pre-rinse and final rinse. In both loops, activated charcoal and mixed bed ion exchanger cartridges ensure that the rinse water quality always meets the strict cleanliness requirements of the boards. Finally, remaining water is removed with hot air in a separate drying chamber. Air knives mounted on top of the cleaning stage and the final rinse chambers reduce any drag-over losses.

Summary

One of the leading Electronics Manufacturing Service providers for the UK and Ireland was able to implement a new cleaning process that offered significant advantages compared to the conventional surfactant-based application while meeting all requirements set by the end customer:

- Better cleaning results in terms of complete removal of flux residues and solder ball formations from the HF assemblies due to the optimal combination of agitation system and cleaning chemistry

- Higher throughput possibilities as a result of a fully automated four-chamber cleaning machine

- Easy handling for the operator due to an integrated touch screen menu with full access to all process parameters

The results of this customer case study can be attributed to the thorough planning and definition of requirements at a very early stage. However, the market research conducted by the company’s Quality & Process Engineering Manager identifying a suitable cleaning process made it also apparent that, even if a performance envelope has been formulated, finding a suitable application can be a difficult task as a wide variety of machines and cleaning agents are available in the industry. The best practical approach was found by utilizing the Technical Center, where a variety of different cleaning machines and chemistries were available for comparative testing with the specific HF assemblies followed by immediate cleanliness qualifications. Therefore, the best solution could be found with a minimal time investment of just one to two days. Since its installation, the cleaning process has been running without any issues providing excellent cleaning results while meeting the production throughput requirements and ensuring easy handling by the operators. The success of this case study proves that a cleaning expert should be consulted when looking for a new cleaning process or desiring to improve an existing one. This is the most targeted way to find the best cleaning solution, even for the highest customer requirements, as cleaning companies have an in-depth knowledge of cleaning equipment as well as chemistry and furthermore, can provide analytical capabilities.

productronica, A2.461

ZUSAMMENFASSUNG

Untersuchungen und Ergebnisse verschiedener Anlagentests, während der Suche nach einem komplett neuen, wasserbasierenden Reinigungsprozess für high frequency Baugruppen im Rahmen eines Baugruppenreinigungsprojekt mit einem größeren UK EMS Provider.

Analyses et résultats de divers tests d’installations durant la recherche d’un processus de nettoyage à base d’eau, complètement nouveau pour les modules high frequency, dans le cadre d’un projet de nettoyage de modules avec un provider UK EMS plus grand.

Share: