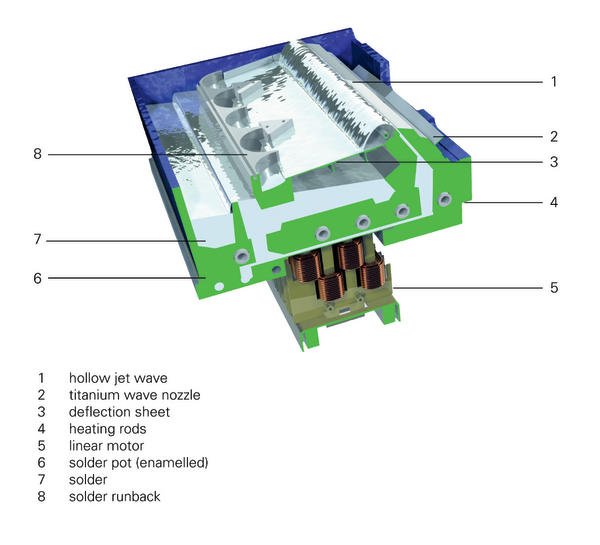

The demand for more sustainability cannot be ignored. The effect this will have on the electronics industry will possibly be even more pronounced than on the automobile industry; according to a recently published analysis by the UNO, the manufacturing of electronics is said to encumber the climate many times more. With its patented electro-magnetic soldering pump, the Swiss enterprise Kirsten, has been providing a response to the ever-increasing problem of emissions. Reportedly, its hollow wave has not only paved the way to reliable, lead-free soldering. The solution, track-proven in over 2,000 cases, distinguishes itself with a substantially lower consumption of energy, solder and flux.

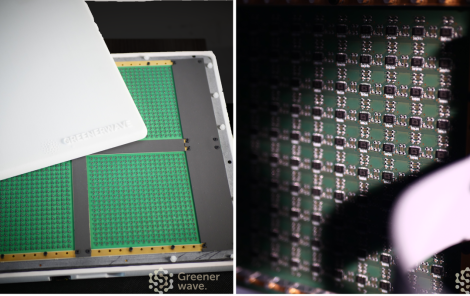

The company’s soldering system „modula wave“ can be seen in its definite form for the first time at the SMT 2007 in Nuremberg. The system solution, newly conceived from scratch and including the soldering pump with the shortest moistening time, it distinguishes itself from the firm’s JET generation firstly by its completely horizontal alignment of the individual components, realized for the first time ever. This makes the system as a whole not only more elegant, the absolutely horizontal transfer direction also means additional precision. An additional advantage is to be found in the continuously modular concept of the new system solution. This enables, among other things, an entry configuration which can be adapted to individual requirements and investment capital.

Another advantage of the proprietary hollow wave is the high precision and reliability, even when soldering electronic miniatures. All of these benefits which are relevant to cost effectiveness are even more prevalent in the new system generation. The regulation and control management over the entire system represents a substantial innovation. The user will be able to experience this through the logically constructed, transparent user guidance. The ‚brain‘ of the modular system generation provides wholly constant process conditions and, together with the hollow wave, enables maximum output quality.

SMT, hall 8, booth 424/ Nepcon UK, M80

EPP Europe 441

Share: