For nay-sayers who about a decade ago, started doubting the viability of in-circuit test as a business, the author drills down for an in-depth look at a thriving sub-eco-system that is supporting this manufacturing test stalwart. The In-Circuit test (ICT) technology has more than 30 years of history from the time where the Printed Circuit Board Assembly (PCBA) manufacturing started with automatic insertion of through-hole components to the proliferation of Surface Mount Technology (SMT) components and Grid Array (BGA) package of Integrated Circuit devices.

Jun Balangue, Agilent Technologies

The manufacturing process is still the major contributor of PCBA failure during board test (ICT and Functional test). This is one of the key reasons why throughout the 30 years of manufacturing boom, ICT still remains the board test system of choice for Electronics Manufacturing Services (EMS) companies for catching structural defects on PCBA For mission-critical industries such as military , medical, automotive and industrial manufacturing, ICT is almost always an indispensible mode of PCBA quality check and assurance.

Here’s an overview of the PCBA fault spectrum arising from the manufacturing process:

- Defects from SMT placement-caused misalignment, missing parts, incorrect/wrong parts, bent leads, wrong polarity, extra parts which will lead to opens, shorts and wrong value components during ICT.

- Defects from wave soldering and reflow ovens causing insufficient solders, board flooding, bridging, solder crack, wetting, as well as voiding causing defects such as open and shorts during ICT.

- Defects from the use of manual hand insertion of odd-shaped components, causing bent pins, wrong parts and wrong polarity that result in opens, shorts and wrong value defect during ICT.

- New technology such as high speed signals, high current power requirements, high density interconnects causing failures on ICT such as opens, shorts; as well as loss of test point access which will translate to lower test coverage during ICT and higher failure during functional test, which is harder to repair.

Despite rapidly-changing demands brought on by increasingly complex PCBAs, with boards seeing higher speeds, higher power requirements and relentless addition to PCBA density, manufacturers of in-circuit testers have managed to take these challenges in their stride. These ICT vendors are continuing to upgrade features and capabilities to address new PCBA technology challenges.

The resilience and success of in-circuit testers as a mainstay of manufacturing test strategy may be attributed to the following:

- Strong demand from Electronics Manufacturing Services (EMS), Original Design Manufacturing (ODM) and Original Equipment Manufacturing (OEM).

- Deeply-entrenched ICT business ecosystem, comprising test programming solution, fixturing services, ICT test probes, and software solutions such as CAD translation, DFT, and test coverage analysis)

- Availability of ICT test engineers and ICT system support services at every manufacturing site, worldwide. This represents a veritable pool of engineering human resource.

ICT system market

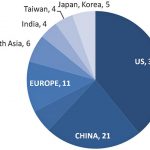

Strong growth in the electronics manufacturing sector has translated into better than expected result for the ICT business. For PCB automated test equipment (ATE) vendors, industry statistics indicate that ICT systems account for about 30 % of the total revenue of $1.4 billion for these vendors. The top three ICT vendors, Agilent Technologies, Teradyne and Test Research Inc together account for more than 80 % market share of the ICT revenue.

Some market analysts had forecast that ICT systems revenue will decline over the years due to loss of access and shrinking PCB size. However, the year 2010 saw strong ICT system sales growth for the top three ICT companies. This is mainly attributed to the strong growth in the electronics manufacturing sector, which needs reliable test solutions that are also compatible with their existing ICT systems, which number in the thousands across the EMS footprints.

Due to its entrenched popularity as the board test solution of choice, a distinct ICT ecosystem has developed over the years, sustaining business opportunities for various parties:

1. Fixture Vendors and Test Programming houses

Fixture vendor businesses that supply both the ICT fixtures and development of test programs needed to test the PCB have seen steady business. A number of companies have proliferated globally to support the ICT business.

Fixture and test programming service providers usually locate their businesses near to key manufacturing sites. This ease of access itself further underpins the test engineers’ preference for in-circuit test as their board test of choice.

Fixture vendors have also demonstrated innovative value-added services, such as developing and introducing new fixture technology which can access 20 mil testpoints for high-density PCBAs.

2. ICT test probes vendors

ICT test probes are a cost-effective and reliable means of enabling the test fixture to access the PCBA. The majority of probe suppliers in this high-precision tooling business also have sales offices and distributors in the vicinity of every key manufacturing site globally.

3. Software solutions (DFT, Test Coverage Analysis, CAD Translations)

An indispensible partner in the ICT ecosystem is the availability of 3rd party software solutions that provide DFT solutions and coverage analysis for NPI engineers to assess the testability and test coverage analysis of their test programs, as well as CAD translations software for test program development engineers and solution providers.

4. ICT Test Engineer and ICT system support services

Last but not least, and perhaps one of the most important factors driving the continued popularity of the ICT solution is the presence of ICT test engineers and ICT system support services at every CM, ODM, OEM manufacturing location worldwide. Unless there is a sudden massive tipping point, it is unlikely that these roles will diminish anytime soon. This global army of ICT engineers will themselves continue to drive demand for better tests, to ensure that product quality continues to improve.

Zusammenfassung

Auch nach 30 Jahren erweist sich die In-Circuit-Technologie immer noch als ein starkes Tool zur Fehlervermeidung. Der Artikel gibt einen gibt einen tiefen Einblick, warum sich das nach all der Zeit so verhält.

Après 30 ans, la technologie In-Circuit se maintient toujours comme un outil fort pour la prévention des erreurs. L’article offre un aperçu détaillé sur la raison de ce comportement après tout ce temps.

Share: