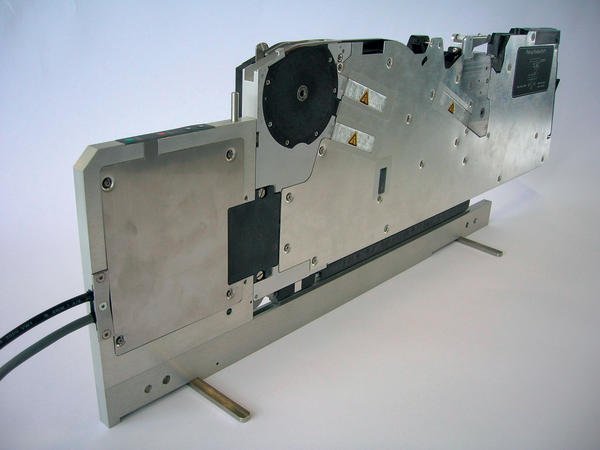

With the Siplace Energy & Data Interface (SSE) for X feeders, the X feeder modules from Siplace can now be operated without a placement machine or pre-setup station. The SSE is suitable for checking, maintaining and repairing X feeder modules. Since it can also be used for pre-setups, it accelerates changeovers of individual feeders on X-Series machines and thus makes the manufacturing process more flexible. All X feeder modules are equipped with a contact-less energy and data interface (EDIF) for the transmission of power and data between the X feeder module and the placement machine via induction and a fiber-optic interface respectively.

The SSE now makes the same technology available without the need for a placement machine. The new option consists of an aluminum frame that holds the X feeder module. This frame contains electronic components that supply the feeder module with the necessary operating power as well as a CAN-Bus interface that makes it possible to read data from the feeder module or send commands to it. Thanks to its compact design, the SSE is ideal for making small feeder adjustments next to the machine. For example, the SSE makes it easy to prepare a replacement feeder and switch it out with minimal machine downtime. One can check and maintain feeder modules just as easily on the SSE without interfering with regular machine operations.

If one wants to use the SSE for setup preparation, one can install an add-on board with a reel arm. This increases the feeder’s stability and provides a steady place for the component reel. The benefits are feeder flexibility and easy feeder setup with no machine downtime.

Productronica, Stand A5.177

EPP Europe 437

Share: