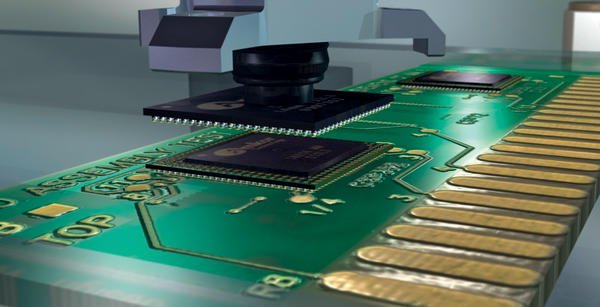

In addition to ever smaller modules, CSP (Chip Size Package) stacking or the Package-on-Package (PoP) principle are becoming ever more important in SMT production. Using slow-motion imaging, a video from Siplace, shows the dip module in action and explains how the principle of the space-saving stacking of components works. Because of its extremely short circuit paths and its many different combinations, CSP stacking offers many benefits, but it also places special requirements on the placement equipment. Placement machines from Siplace master these challenges and offer the speed and accuracy needed for the placement of PoP modules on modern circuit boards in high-volume manufacturing environments.

CSP stacking is particularly popular in applications where processor and memory components need to be combined. The method not only saves a lot of space, but shortens the electric signal paths, minimized high-frequency interference and lets designer combine processors and memory components in flexible ways. The technology is most frequently used for telecommunications and mobile applications.

To reliably place PoP designs, the equipment must be able to do more than accurately place the components on top of one another. It must also apply flux to the contacts of the upper component in order to form solid connections between the two components. To make sure that this is performed quickly and reliably in high-volume environments, the enterprise offers matching dip modules. The dip modules are as wide as three S-feeders, are positioned between the feeders on the table, and have the same mechanical and electrical connections. The flux agent is applied to the dip module’s plate. The plate rotates, and a metal squeegee makes sure that it is distributed evenly. Depending on the component, the depth of the flux agent can vary from 25 to 250 µm (optionally: 125 to 400 µm). Controlled via a force sensor, the placement head dips the component contacts (balls) into the agent to a depth of 50 to 80 % of their height and pauses for a moment (0.25 to 0.7 seconds) in order to ensure proper wetting and the necessary soldering quality.

By integrating the dip modules into their placement machines’ hardware and software, manufacturers of telecommunication and mobile applications can process space-saving PoP designs with the speed and reliability needed for high-volume throughput.

Productronica, Stand: A5.177

EPP Europe 456

Share: