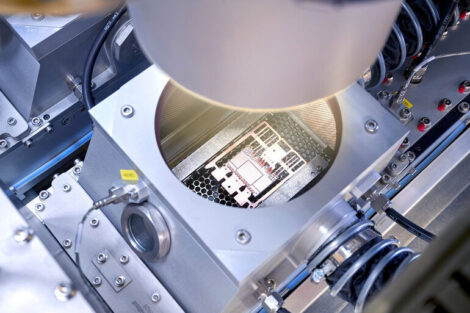

In response to rising demand for Package-on-Package (PoP) applications, Universal has developed new hardware and process technology to accommodate effective flux dipping and soldering for enhanced manufacturing flexibility.

The company’s new fluxer presents manufacturers with a high-speed alternative to conventional systems with the ability to dip multiple spindles. Plus, the new PoP technology significantly enhances manufacturing flexibility by accommodating both flux and solder paste. The combination of an improved containment system and hardened plate sides enables the new system to eliminate common process issues such as paste creep.

Extensive product testing also demonstrated that with a larger flux reservoir, deeper plates and defined materials handling procedures, Universal’s Linear Thin Film Applicator works effectively to overcome problems such as the formation of bubbles in the flux.

“Demand for PoP technology is certainly growing, rendering continual innovation in hardware and process technology absolutely vital for successful implementation industry-wide,” explains Richard Boulanger. “As consumer products in particular favor increased functionality and reduced dimensions, PoP is the obvious solution, saving space on the PCB, enabling thorough testing and boosting performance.”

The company is set to prove its expertise in PoP technology with a schedule of one-day seminars to be held at its Suzhou Technology Excellence Center in China.

EPP EUROPE 430

Share: