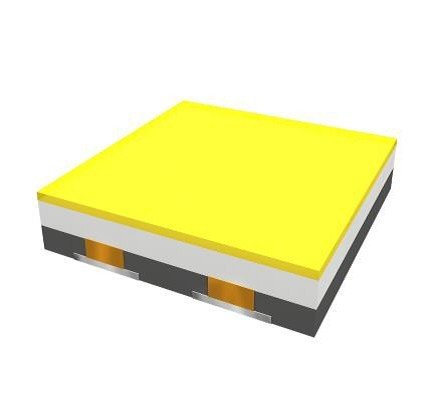

Dow Corning, a leader in silicones, silicon-based technology and innovation, introduced CL-1000 Optical Silicone Binder, a new, more thermally stable, high refractive index (RI) material available only in China that is formulated to expand design options for high-power chip-scale LED packaging (CSP). The latest addition to the company’s portfolio of advanced solutions for LED lighting, CL-1000 Binder offers thermal stability and is optimized for compression molding processes. “The growing adoption of chip-scale packaging is enabling lighting designs that pack increasing numbers of LED dies more densely together in smaller form factors,” said Takuhiro Tsuchiya, global marketing manager. “CL-1000 Optical Silicone Binder is Dow Corning’s response to the rapidly rising temperatures within these emerging applications. A more thermally stable iteration of our high-RI optical materials, this new product is formulated specifically to help enhance the robustness of high power CSP designs.”

Validated through the company’s stringent testing, the superior thermal stability of CL-1000 Optical Silicone Binder enabled it to exhibit lower degradation and improved maintenance of mechanical properties vs. other high-RI silicone encapsulants after 2,000 hours exposure to temperatures above 180° C. The new high-RI material also delivers excellent photo-stability with high clarity to further support reliable performance over the life of LED devices.

New CL-1000 Binder demonstrates good conformance with highly reflective WR-3001 and WR-3100 Die Edge Coat materials, enabling CSP packaging with enhanced reliability over longer periods. The product’s high Shore D60 hardness also enables LED packaging to withstand dicing operations. CL-1000 Optical Silicone Binder leverages the same phenyl silicone chemistry as the company’s other high RI optical encapsulants, which can help optimize the efficiency of next-generation LED lighting designs without costly investments in more powerful LED dies.

Share: