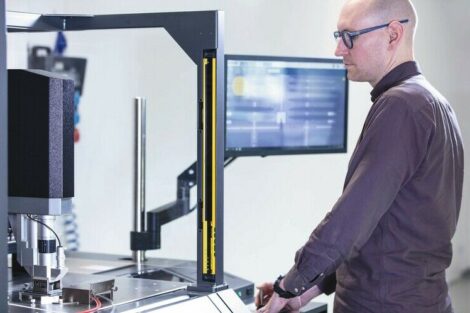

Tough, tiny, and tabletop, the IX-70 ChromAblate on-target inspection and short deletion system from J.P. Sercel Associates delivers high precision and high power in a very small package. It is a laser-based materials processing system built to the company’s industrial standards for ruggedness and reliability, and its compact benchtop configuration and high degree of flexibility make it ideal for a wide range of applications and “touch-up”. Developed for the repair of flat panel displays, micro circuits and wafers, the system can be applied to a variety of micromachining applications, and can be configured with IR, visible, or UV wavelengths to process a wide range of materials from metals to polymers.

A number of innovative features are incorporated into it. Precise control of the laser power is achieved through an integrated adjustable attenuator. Various geometric shapes can be projected onto the work surface through an adjustable aperture for square or rectangular features and for round or other feature shapes, and an optional mask indexing wheel can be utilized. For alignment and inspection of the work surface, the device incorporates a co-axial high resolution CCD camera, adjustable zoom lens, and LCD display for real-time process viewing.

The system is available in multiple wavelengths, and offers high power for its size, up to 90 mJ at 1064 nm, 50 mJ at 532 nm, 11 mJ at 355 nm or 10 mJ at 266 nm. Reliability is built-in with its non-contact technique that provides 24/7 maintenance-free operation. In addition to its benchtop configuration, the system is also available in a gantry-mounted version for large FPD repair.

EPP Europe 442

Share: