Intelligent MES solutions for networking, automation and analyses of production processes is the focus for iTAC Software AG, especially at the SMT Hybrid Packaging show. The company demonstrated how the Industry 4.0– capable iTAC.MES.Suite can interact with IIoT platforms. This creates predictive maintenance scenarios or a collection of useful information, and measures for production using compatible analytics models. The new version of the company’s suite will appear this summer.

A Manufacturing Execution System (MES) is the core to digitalizing value creation processes in modern manufacturing. This requires good interlocking and integration of the MES with other cooperating systems. The suite is industry 4.0 capable and has been used successfully in electronics manufacturing, the automotive industry and many other sectors for many years.

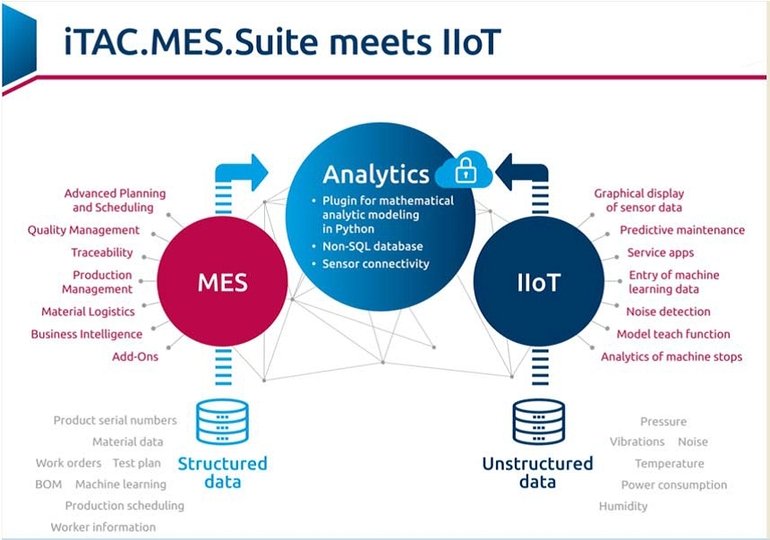

The company showed how the MES works with other systems and IIoT components, within a complete data analytics scenario. This included systems from companies such as Adamos, Microsoft Azure, AWS, IBM Bluemix etc. In the basic version, the MES includes functionalities such as production planning (APS), production management, quality management, materials and logistics, traceability, business intelligence and add-on services. The iTAC.MES.Suite supplies structured data, for example OEE, serial numbers, material data and more. Combined with the IIoT platforms, it provides unstructured data such as vibrations, temperature etc. and services like predictive maintenance thus delivering intelligent complete solutions. These can be created individually, following the use cases from KMU, as well as by large companies.

It also allows a continuous flow of information to ensure transparency and evaluation of production processes using standardized and customer-specific KPIs. The version 9.01, which will be released in the summer, includes features and extensions that target efficient digitalization of manufacturing processes.