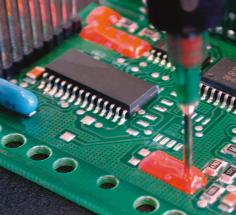

The Dymax 9–20553 series temporary masking materials cure within seconds when exposed to UV light. These are solutions for a wide range of electronic assembly applications such as bonding, potting and protecting. Various viscosities are available to support easy dispensing. The masks are water-soluble and leave no silicone, ionic contamination or corrosive residues after rinsing. Alternatively, strippable temporary masks are offered. The materials 9–20318-F and 9–20515 also ensure reliable protection of PCBs including FR-4, ceramic and gold fingers during coating or soldering applications. A fluorescent version is available for detection with visual inspection systems. The main advantages claimed by the supplier are cost reduction due to the fast cure and easy handling of the one-component materials. MIL, IPC and UL approvals are available. All these materials for assembly applications are RoHS-compliant and support lead-free processes. The company also supplies curing equipment such as UV spot lamps, flood lamps and conveyorized systems.

Productronica, Booth A3.524

EPP EUROPE 439

Share: