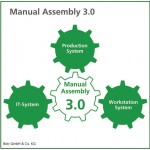

In recent years hardly any process in the factory has gained so much importance as manual assembly. Previously, a solution for small series or series start-up, it stands today for efficient added value and is often the only means to meet the requirements of high variant diversity and short product life cycles. Bott GmbH & Co. KG sees the beginning of a new era of manual assembly in the merging of the production system, the IT system and assembly workstations into an integrative system.

Bott GmbH & Co. KG, Gaildorf (Germany)

However, together with their importance, the complexity of factors which contribute to the success of manual assembly increased at the same time.

Complexitiy in focus

Extensive production systems define processes and resources. IT systems provide process reliability, control material flow and delivery performance. Assembly workstations became active parts storage and were equipped with all kinds of process technology. Parallel to this development, mega trends such as globalization and demographic change put demands on modern manual assembly which are higher than ever.

According to the company, the world’s leading manufacturer of vehicle workshop equipment and workstation systems, the challenge of the future is to combine the main success components of manual assembly such as processes, technologies and equipment with each other in order to achieve holistic use. In achieving this objective, the company sees the beginning of a new epoch, Manual Assembly 3.0. The company uses this term to define manual assembly as an integrative system which comprises the production system, assembly workstations and IT systems that comprehensively deal with the issues of the adaptability of the factory, competitiveness in the global market and demographic change.

In contrast to current practice, which the company refers to as Manual Assembly 2.5, what distinguishes 3.0 is the integrated approach already during the development of individual system components and matching them to one another. So far, assembly workstations were merely fitted for the principle of lean production and subsequently adapted to IT systems.

This leap forward can be compared to the leap made from Manual Assembly 1.0 into the 2.0 generation, which established continuous production lines with the daisy-chaining of standalone workstations and, at the beginning of last century, characterized the start of the industrial revolution. That is how the company views these past eras.

Intelligent processes

In practice, bott sees decisive advantages in Manual Assembly 3.0 as compared to the previous status quo: Production IT finds workstations that are innately data entry stations and receivers. That means they are able to seamlessly integrate printers, scanners, laser markers or terminal devices for employee time recording and time management, along with any plug-ins.

Process planners and quality assurance employees incorporate their testing techniques, assistance systems and automatic logging directly at the assembly point and recognize the assembly station as a process station with bidirectional links.

Material logisticians implement principles such as Kanban and Fi-Fo without any restrictions or install removal monitoring and worker guidance systems such as pick-to-light exactly at the point where workstation, parts storage, material storage and IT systems merge into one whole.

Job order planners and schedulers use the integrative System 3.0 since orders can be much more easily blocked, transferred or brought forward.

Designed with the perspective of demographic change in mind, 3.0 has elements which meet the requirements of employees and ergonomists through adequate workstation design or assistance systems. For factory planners and investors, Manual Assembly 3.0, with its approach as an integrative system comprising the production systems, IT systems and assembly workstations, provides flexibility and investment protection at the same time.

For the first time, the company was using the term Manual Assembly 3.0 in association with the market launch of the new avero workstation system in the fall of 2013.

SMT Hybrid Packaging

Booth 7-532

Zusammenfassung

Kaum ein Prozess in der Fabrik hat in den vergangenen Jahren so an Bedeutung gewonnen wie die Manuelle Montage. Früher Lösung für Kleinserien oder den Serienanlauf, steht sie heute für effiziente Wertschöpfung und ist oft einziges Mittel um den Anforderungen an hoher Variantenvielfalt und kurzen Produktlebenszyklen gerecht zu werden. Im Zusammenführen von Produktionssystem, IT-System und Montagearbeitsplätzen zu einem integrativen System, sieht Bott den Beginn einer neuen Epoche in der manuellen Montage.

Il n’y a pour ainsi dire aucun autre processus dans l’usine qui a pris au cours des années passées autant de signification que le montage manuel. Constituant autrefois une solution pour les petites séries ou le démarrage dela production en série, il est synonyme aujourd’hui de création devaleur efficace et ilest souvent le seul moyen pour s’acquitter d’un très grand nombre devariantes et de cycles courts pour la durée devie des produits. En associant le système deproduction, le système informatique et les poste detravail pour le montage pour en faire un système intégré, Bott annonce le début d’une nouvelle époque pour le montage manuel.

Share: