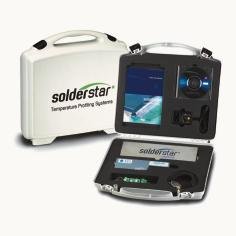

Three easy-to-use thermal profiling packages are designed for the demanding technical and budgetary requirements of low, medium and high volume lead-free electronics manufacturing environments: Solder Star Lite, Solder Star Plus and Solder Star Pro.

The Solder Star range is entirely lead-free compliant and fulfils the need for fast, precise profiling and process control. SolderStar’s clients can achieve an optimal thermal profile after 30 minutes and perhaps two or three runs through the reflow oven, compared with hours, if not days, of frustrating trial-and-error work with other systems.

Incorporating up-to-date battery technology, Solder Star’s instruments have a higher working temperature than most of the other alternatives. Furthermore, only 20–25 mm thick, they are the slimmest profilers on the market. This makes them ideal for use in modern reflow ovens with limited tunnel height.

Solder Star Lite is ideal for the small manufacturer or an entry-level or second system. It offers high performance profiling on a limited budget, ensuring correct settings are established and maintained. Solder Star Plus offers powerful additional features, including an industry-standard 6-channel datalogger with a high-performance heat barrier, and simulation software for ultra-fast profile set-up.

For the ultimate in temperature and process profiling, Solder Star Pro includes a datalogger with up to 12 channels for demanding processes and PCBs, as well as a comprehensive suite of full-feature software that includes SPC capabilities. Like Solder Star Plus, it can be used with accessories to optimize wave soldering processes and profiles, and is ideal for medium to large manufacturers who profile continuously as part of an ongoing quality control strategy.

EPP EUROPE 427

Share: