Lacquers for the process-safe and quick production of high-tech PCBs with the most advanced manufacturing technology as well as lacquers for the protection of PCBs, in order to guarantee a reliable functionality – considering the steadily deteriorating climatic usage conditions Lackwerke Peters, Germany, present a considerable production range, which reflects the requirement profiles for circuit printing lacquers and conformal coatings. Here some particularly interesting highlights:

LDI, HDI, TK6, UL 94, IPC, LED exposure: Whether for generating finest traces on HDI printed circuit boards by laser direct imaging (LDI) or for obtaining highest resolutions for exposure on the new LED exposure units – the high-performance Elpemer solder resists demonstrate their strengths in all areas.

The solder resists of the Elpemer 2467 series (aqueous-alkaline developable) meet and the solder resists of the Elpemer 2469 SM-HF series (polyalcohol developable) even well exceed current requirements on the thermal cycling resistance up to and including the temperature class TK6 per Bosch Y 273 R80 029. The photo-imageable polyalcohol developable solder resists of the series 2469 SM-HF are halogen-free in terms of the two relevant directives JPCA-ES-01–1999 and IEC 61249–2–21.

The accredited test institute Trace Laboratories-East in the U.S. has recently issued reports on tests performed per IPC-SM-840C which confirm that the Elpemer 2467 and 2469 SM-HF solder resist series‘ fulfil/exceed the test criteria for class T (Telecommunications, also includes Bellcore/Telcordia requirements) and H (High reliability). Both solder resist series‘ have been awarded the best flame class rating UL 94 V-0 by Underwriters Laboratories under Approbation No. File E 80315.

A broad pre dry window, low exposure energy and short exposure times ensure high productivity and economic processing of these solder resists. Their high pencil hardness and scratch resistance after final cure afford excellent protection from mechanical damage during handling. Moreover, due to the solder bath resistance – also in lead-free soldering processes – and compatibility with numerous electroplating and chemical surface finish processes both series can be used in many different facets of printed circuit board fabrication. These solder resists are available for all common application methods.

White stays white: New photo-imagiable Elpemer solder resist and marking ink. The increased temperature stress during lead-free soldering processes, especially during reflow soldering causes a strong yellowing of the solder resists as well as of the marking inks which are available on the market. Of course the electrical and mechanical properties are not influenced negatively, however disadvantages in the reflectivity occur, which is very important for the lighting technology. For this reason the company has introduced new products that meet the optoelectronics requirements. Besides the already established thermal curing 2-pack solder resist SD 2496 and the 2-pack marking ink SD 2696, it now offers an extremely colour-stable photoimagiable solder resist Elpemer FP 207–1010 and a photo-imagiable marking ink Elpemer FP 207–1015. The application of the yellowing-stable lacquers is executed by screen printing.

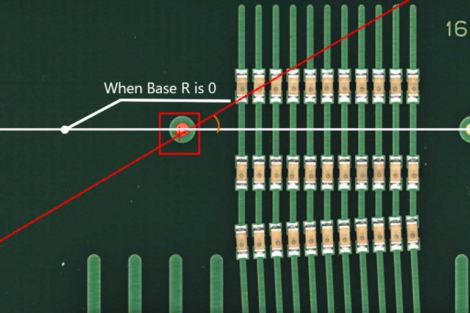

Secondary Imaging Technology (SIT for short) is the term covering the realisation of various surface finishes on a printed circuit board: Parts of the copper surface that should not be finished are protected by a resist and can be given a different treatment after the resist has been stripped.

The company has optimised the already relatively short screen open time of its plating resist SD 2149 SIT which was especially developed for use in SIT technology: Particularly positive characteristics that distinguish the enhanced SIT resist SD 2149 SIT-HS are its milder odour and broad processing and drying window (HS = high boiling solvent). It is a black, oven drying screen printing ink.

The plating resist SD 2149 SIT-HS protects, for example, copper surfaces during the ENiG process and enables the later application of a partial OSP surface. The very good adhesion and resistance to the ENiG process guarantees protection of the copper from attack by the Ni/Au baths. SD 2149 SIT-HS does not contain any iron-based pigments.

While SD 2149 SIT-HS, applied by screen printing, reaches its limits at a resolution of around 150 µm, resolutions of < 50 µm can be achieved with the photoresist FP 2007–0124.

FP 2007–0124 is distinguished by a high resistance to ENiG processes and is strippable in special alkaline strippers (e.g. RS 610 by Atotech).

NANO conformal coating Elpeguard SL 1303 NANO-AQ-FLZ: This new ink system is a water-borne conformal coating based on acrylate resin with NANO filling agents. By using NANO filling agents it is possible to endow transparent inks with the beneficial properties of inorganic fillers without inhibiting the clarity. The filling agents used in the NANO conformal coating improve the barrier effect – and thus the film density -, adhesion and chemical resistance. First and foremost, however, the NANO conformal coating exhibits a high elasticity and high mechanical stability. On the one hand this results in an exceptional scratch and abrasion resistance, and on the other hand in an excellent cold flexibility and thermal shock resistance. Naturally, the NANO conformal coating meets requirements per IPC-CC-830. For repair purposes, this colourless transparent, fluorescent conformal coating can be easily removed from the assembly by means of solvents.

Productronica, Stand B3.331

EPP Europe 442

Share: