The Medalist SJ50 Series 3 Automated Optical Inspection system (AOI) launched by Agilent Technologies expands on the existing SJ50 product line, providing industry-leading optical performance. The imaging platform improves ease of use, throughput, component location and supportability, as well as enabling manufacturers to cope with emerging technologies, such as 01005 components.

In addition to helping manufacturers achieve a better bottom line through faster time-to-market and cost efficiency, the system offers further enhancements to help manufacturers address emerging technical challenges. For instance, low-contrast components have presented inspection issues industry-wide. The algorithms included in this AOI system are designed to bring greater image clarity to low-contrast components, providing the end-user with better defect analysis capabilities. The image clarity results in lower false-call rates and improved defect detection.

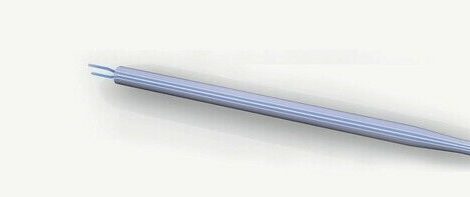

This AOI system is ergonomically advanced with significant user and system interfaces. According to the company, a key differentiator is the unparalleled flexibility inherent in the technology. It can be deployed in a 2D paste, pre-reflow, mixed-mode and post-reflow environment while quickly converting the optics head for inline 3D solder paste inspection. This flexibility offers manufacturers a system that can be easily deployed in a multitude of line positions for those sites that are new to AOI or those that are growing and have ever-changing needs.

Reportedly, both the Medalist SJ50 and SP50 Solder Paste Inspection systems integrate key enabling technologies for a degree of accuracy and flexibility not previously seen in AOI. Interchangeable lighting heads and the firm’s unified platform technology allow the systems to be redeployed at paste, pre- or post-solder as needs change. New techniques such as Solid Shape Modelling deliver the highest-resolution 3D images, while links to downstream repair stations and statistical process control tools allow better control over collected data.

electronica, booth A1.606

EPP Europe 445

Share: