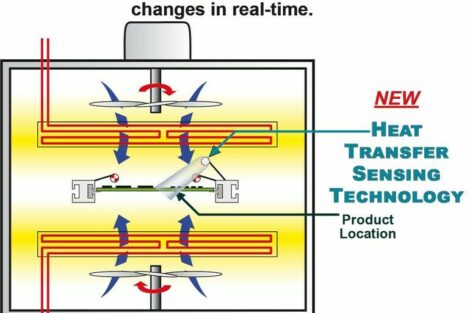

An important topic presently occupying the thoughts of PCB manufacturers is the current outcry for higher thermal resistance of PCBs. The surrounding temperatures at which electronic assemblies are operated, particularly in the automotive sector, are rising; moreover, the thermal stress due to the inherent heat from the growing population density is escalating.

“Thermal stress” – the permanent load at elevated temperatures – as well as “thermal shock” – thermal cycles over a broad temperature range (in the case of material combinations mechanical stress is also of great importance due to the different coefficients of thermal expansion) – are aspects from which solder resists and their protective coatings have to be increasingly evaluated.

Lackwerke Peters presents a solution for such increasingly harsh operating conditions with the introduction of its photoimageable Elpemer solder resists. Used in combination with the Elpeguard conformal coatings of the Wepesil silicone-rubber casting compounds, the solder resists show an excellent performance in thermal cycling tests (TCT of –40 up to +150 °C) as well as exceptional permanent temperature resistance (2000 h at 150 °C).

Even this load affects neither the electrical insulation properties nor the coating condition with respect to cracking or delamination. High resistance against migration and against chemical finishing processes or lead-free soldering processes completes the requirement profile of a modern solder resist.

The company’s conformal coatings offer excellent protection against moisture and corrosion and fulfil further requirements of the IPC standard IPC-CC-830B, one of the most important IPC standards for state-of-art assembly manufacturing and internationally accepted for the qualification and evaluation of conformal coatings.

The conformal coating SL 1307 FLZ offers advantages in productivity on account of its extremely fast curing and is also distinguished by a TCT resistance of –40 to up to +150 °C. Its short run temperature resistance acc. to EN 60216 (5000 h) is 150 °C, its permanent temperature resistance (20 000 h) is 125 °C.

If a higher temperature resistance or protective effect is required, the manufacturer recommends the use of its silicone-rubber casting compounds that are distinguished by their high temperature resistance up to 200 °C, partly even up to 250 °C. On account of their high elasticity, material tensions during thermal cycling are considerably reduced. For applications in hermetically encapsulated casings an addition cross-linking casting compound, such as VU 4694 E, is particularly suitable since there is no risk of reversion resulting from separation products.

All described products comply with current European devices, such as the RoHS directive 2002/95/EC, the European End-of-Live Vehicles directive 2000/53/EC (ELV) and the WEEE directive 2002/96/EC.

electronica, booth A6.A26

EPP Europe 437

Share: