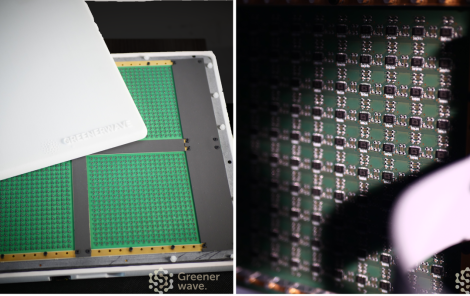

With „modula wave“, a new generation of soldering devices from Kirsten Soldering, the Swiss pioneer in lead-free soldering is setting new landmarks, qualitatively as well as economically. The control management over the entire system represents a substantial innovation. This offers the operator a logical user guide from A to Z. Two central components, working in optimal interplay, provide maximum output, – the „brain“, viewed over the GUI, which ensures absolutely constant process conditions, and the electromagnetic soldering pump which can be seen as the heart of „modula wave“ and which operates without any moving parts, thereby working almost wear-free.

A benefit of the patented hollow wave, which has been successfully installed over 2,000 times, is its economy in respect to energy and solder, thanks to the smallest possible soldering bath. High precision and reliability are just two further advantages, both are based primarily on the extremely short wetting time, whereby the Kirsten soldering solution is also predestined for highly-sensitive components. Another important plus point is the pulling down effect of the hollow wave. Thanks to the Bernoulli effect holding down clamps are not necessary.

In addition to the integral process management and the horizontal transfer system, a further advantage is found in the completely modular concept. In this way, „modula wave“, provides an attractive solution also for small companies. According to requirements and investment capabilities, such a set-up lends itself to being extended up to the most comprehensive in-line operations.

EPP Europe 417

Share: