Every year, millions of color television sets are produced. More and more, classical CRT TVs are replaced by LCD TVs. For example, revenues in the TFT LCD panel market reached 71.1 billion dollars, up 35. 7 % from the previous year, buoyed by a strong demand for large size panels and an increase in shipments [1]. About 76 million LCD TVs will be sold worldwide this year and about 99 million next year. By 2011, sales of 165 million LCD sets are forecasted [2]. In particular, small and medium-sized LCD displays for mobile phones, MP3 players, cameras, etc. are demanded. This demonstrates the current importance of LCD technology in display production.

The production process of LCDs has been continuously optimized over the years and today, large amounts of displays can be produced at low prices. However, they reveal some technical disadvantages. For example, LCD displays do not emit light on their own, but must be illuminated from behind by a so-called back light unit (BLU) for applications like in mobile phones, laptops, and television sets. This is an unpleasant aspect for mobile applications as the BLU consumes comparably much energy. Therefore, development is going on: Some mobile phones are already equipped with novel OLED displays. The abbreviation stands for organic light-emitting diode and describes, to put it simple, a component made of a self-lighting array of semiconducting layers, similar to a classical LED. However, the individual layers consist of organic substances (Figure 2).

Advantages of OLEDs

OLEDs consume clearly less power than LCDs: No back light unit is required and, contrary to LCDs, where the complete BLU is continuously switched on and, thus, consumes power, only those pixels emit light which are currently required. A further advantage of OLED technology is the fact that by avoiding the rigid and space-consuming BLU, a more lightweight and thinner design is possible. Furthermore, from the user’s point of view, the following aspects are important: The viewing angle is much larger and the colors are brighter and more brilliant. In principle, OLEDs offer the potential to be produced at the same costs like LCDs or even cheaper. Today, LCDs are still clearly less expensive in production but it has to be kept in mind, that a very highly developed technology, LCD, is compared to a technology which is still in its infancy, OLED. The market forecasts predict OLED a definitely promising future.

Particularly, as their use is not restricted to the already giant display market: OLED modules shine so bright that they can also be used for lighting purposes. If the efficiency of OLED lamps is further increased, they will probably be able to replace classical light bulbs or even fluorescent tubes one day. Moreover, due to their absolutely flexible design, they offer tremendous opportunities for designers that cannot be realized with any other technology.

Last but not least, OLEDs offer the opportunity to produce flexible, bendable light-emitting layers or displays which could be interesting for future applications like arbitrarily shaped light sources.

One precondition: Highly efficient sealants

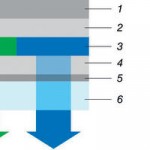

Besides all advantages described, OLED technology involves several challenges for developers: The organic substances are highly sensitive to humidity and oxygen. This is due to the fact that the luminous polymers and the cathode material – which is calcium in many cases – are affected and destroyed in contact with humidity or oxygen. Therefore, the component must be completely and permanently protected against it. Generally, this is achieved by encapsulating the OLED between two glass plates, that is, the OLED layer structure is deposited on a glass substrate to which a cover glass is bonded by means of an adhesive which is dispensed along the edge of the OLED structure. Neither oxygen nor humidity can penetrate through the glass plates, so that the only possibly way left for oxygen or humidity to reach the OLEDs is that through the adhesive. Therefore, the development of suitable adhesives with an extremely low permeation for oxygen and humidity is a decisive precondition for the realization of OLEDs with a sufficient lifetime.

But what does sufficient lifetime mean? Or in other words: What permeation rate is acceptable in order to reach a defined lifetime? This depends, for example, on the size of the display as, with increasing display size, the OLED area increases proportionally faster than the circumference of the display through which humidity can penetrate [3]. Generally, the permeation rate (or water vapor transmission rate = WVTR) is measured in g/m2 x d. It indicates how many grams of water penetrate an adhesive layer with an area of 1 m2 and a thickness of 1 mm per day. The maximally allowable permeation rates determined in a model calculation are summarized in dependence of the screen size in table 1.

Generally, the adhesives are light- or UV-curing epoxy resins. The encapsulation process flow is shown in figure 3. After producing the OLED structure, an adhesive bead is applied around the structure under exclusion of humidity and oxygen by means of needle dispensing, jetting, or screen printing. Subsequently, the cover glass is attached and pressed, and the adhesive is irradiated and cured with UV light from below through the substrate glass. After a typical exposure time of 30 to 60 seconds, the adhesive is strong enough for further processing of the OLED.

One outstanding property of DELO’s OLED encapsulation materials is the fact that thermal post-baking is not necessary, contrary to many currently available products. Their full efficiency is achieved by pure light curing, allowing clearly shorter process times in mass production and leading to considerable cost savings. In November 2007, the company received the Radtech Europe Award for the development of the innovative UV-curing epoxies for OLED-Displays in the sector “industrial coatings and adhesives”: The prize goes to innovative technologies in the sector of radiation curing and is awarded by the Radtech Europe association, that is a worldwide operating organization aiming to support and promote the use of light-curing technologies.

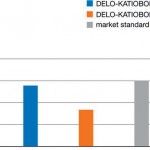

Figure 4 shows some typical WVTR values of one of the company’s standard OLED sealants. In order to prevent very long measuring times, they are normally carried out at increased temperature and humidity. With the WVTR values measured, these products rank among the best OLED encapsulation compounds which are currently available.

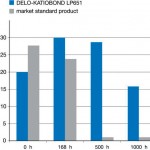

Besides low permeation, there is a second decisive parameter which must be considered as well. Besides diffusion of oxygen or water through the adhesive, diffusion along the interface between adhesive and glass is also possible. This kind of diffusion is less dependent on the adhesive’s permeation, but on good adhesion of the adhesive to the glass plate. Of course, not only the initial strength is important, but also and particularly the long-term resistance of the bonded connection. Even after exposure to, for example, 85 °C / 85 % r. h. for 500 hours, the adhesion must still be high enough to prevent any diffusion along the surface. The excellent behavior in this regard of the company’s OLED sealant is demonstrated in figure 5. The adhesion to glass after storage is nearly as high as that without humidity storage – an indicator for an efficient and long-term resistant encapsulation.

All in all, the following properties are decisive for an efficient OLED encapsulation compound:

- Low WVTR and OTR values (oxygen transmission rate) in order to reduce the transmission of water vapor and oxygen through the adhesive

- Excellent adhesion of the adhesive to glass as well as a good long-term and humidity resistance of the bonding in order to reduce the transmission of water vapor and oxygen along the interface between adhesive and glass

- Suitability for fast, highly automated processes in order to allow for the high production quantities expected in the future

The future shines brighter

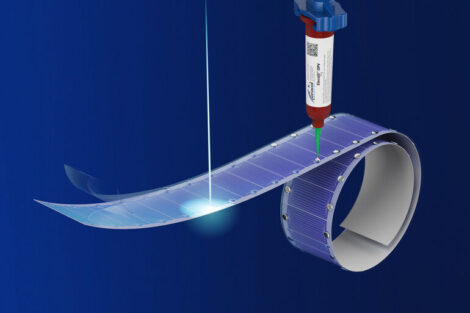

The current research in the field of OLED display sealants at DELO concentrates on a further improvement of the existing products and on the adjustment of the standard sealants to special customer requirements. Here, a further reduction of the WVTR values and a further improvement of the humidity resistance are in the focus of interest. If the technological progress continues, the OLED technology is looking at a great future and the users can look forward to brilliant and bright colors of their mobile phone displays or future television set generations. From an industry point of view, OLED signifies an even greater product variety and economical energy consumption. Moreover, the development of totally flexible and bendable systems goes on (figure 6). This opens new application possibilities not only in the field of flexible displays, but also in many other forward-looking technologies, such as the encapsulation of flexible solar cells.

EPP Europe 445

Share: