Kirsten Soldering AG has incorporated the well-known Jet Wave soldering module into a fully modular system, The Modula, which allows not only variability in the various conveyor speeds so that preheating times are co-ordinated with the flux requirements and molten solder contact times are kept to a minimum but it also allows for factory expansion and the ability to rapidly interchange between one solder type and another by using modular solder pots. The Jet Wave uses high thermal efficiency to minimise wetting times and has proven itself ideal for soldering sensitive components. Because it is a single wave, the risks from thermal shock are much lower than for twin wave systems. Modular control of each zone, or module, allows the optimum parameters of temperature profile to be set for each job. The Jet Wave module has been used in Kirsten products for many years and a K 7000 series system has been in use at the Calw-based company Robert Seuffer GmbH for some time manufacturing a variety of products from the automotive, consumer and industrial electronics sectors of industry.

Robert Seuffer GmbH & Co. KG is a family-owned company employing 460 staff and turns over around 75 million euro per annum in its Calw facility. The company has developed core competence in advising on, developing and then manufacturing customer-specific products such as electronic and mechatronic modules, sensors and switches for the automotive, consumer and industrial electronics sectors. Customers include household names such as Brose, Valeo, MAN, Daimler, DAF, Miele and many others. “We see ourselves as a strategic partner being able to develop and manufacture reliable, innovative and cost-effective products for all our customers,” says Thomas Guenther, head of production and logistics at Seuffer. “We base our production activities on the principles of teamwork and the Toyota production system in order to develop a value-add chain adapted to the needs of the company and customer. We maintain a partner relationship with our machine suppliers in order to sustain mutual profit. Our own jig and fixture department together with the test and quality assurance group give us the flexibility required by ever-more competitive markets”. The company uses fully automatic SMT assembly lines, utilises various soldering processes and configures the automation to suit the various lot sizes.

More than nine years of successful collaboration

The Seuffer company has been working closely with Kirsten Soldering AG since 1999 and regards the K 7000 series machines as the predecessors to The Modula. “The soldering principle with The Modula is the same as for the K 7000 series,” says Ulrich Ohngemach, who is responsible for technical planning and occupational safety at Seuffer. “Our collaboration with our Swiss partner, Kirsten-Soldering AG, has been working well for over eight years from the time when we installed a prototype K 7000.” There was, of course, a great deal to optimise with a completely new soldering system and this learning curve was simplified by the rapid response from sales and service teams. “We knew we would always get very fast support and could rely on each other,” says Ohngemach.

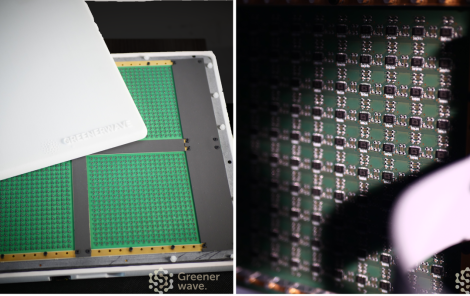

“The prototype K 7000 was replaced in 2006 by a pair of K 7360s, one for Sn/Pb production and one for Pb-free. The machines not only require little floor space but use the patented linear motor driven pump in their solder modules so that there are no moving parts, apart from the solder, and this gives us very high solder joint quality from a very small solder pot which gives us very low energy consumption. The rapid wetting time available from the Jet Wave, plus the programmable wave height (5 mm to 25 mm in 1 mm steps) plus the optimised wave speed (around 0.8 m/sec) ensures very high quality solder joints for every application.

It is very important for us to treat our customers’ PCBs in the most benign way possible and therefore the low thermal stress allied to no fixturing for component hold-down gives an advantage with assembly quality.

The machines are clearly designed for maximum productivity and we have also configured them for fast throughput,” says Ohngemach. “The small solder pot capacity, 60 kg, is not only efficient in heat-up energy but it also reduces the waste from dross and replacing contaminated material. We thus achieve a stable process at low cost.” In order to allow maximum efficiency from our workstations, we developed, in conjunction with Kirsten-Soldering AG, a special lift unit that can remove or replace individual PCB carriers without causing bottlenecks or preventing other products from soldering when required. Finally, we decided that, for us, a nitrogen blanket to minimise oxidation would be a better system than a fluid blanket. Although it costs more than fluid, it allows higher throughput.”

Modular design

Seuffer has established some key parameters when choosing equipment. For soldering, they need low operating costs, low maintenance, low energy costs, high flexibility and very low defect levels.

Kirsten can achieve all of these and The Modula adds to the list by offering modular expansion as factory needs dictate. As Ulrich Ohngemach states: “The obvious advantage of the concept is its modularity and the possibility of expansion gives added value to previous investments, whilst retaining all of the other advantages.”

Modula wave

One of the reasons for developing The Modula was to allow those companies that needed both Sn/Pb soldering and Pb-free soldering to be able to change rapidly from one to the other and back again while not using any more floor space than that used by a single machine.

Changeovers are measured in minutes rather hours. For Ulrich Ohngemach, a Kirsten Modula will be an interesting option for the future even though the existing machines are young and very reliable. The expansion possibilities make it attractive as does the horizontal soldering conveyor, which, along with the modular layout, makes this concept unique.

Pioneer in lead free soldering

“Whether the requirement be for high density, fine pitch, conventional, mixed technology or selective joints, durable and high quality interconnections will always be required,” says Bruno Ghidotti, CEO of Kirsten-Soldering AG. “Two factors are critical for the production of reliable interconnections: precision and gentle treatment, and we have been achieving these for 25 years.

It is not surprising that the consistent output quality and low defect rate occurs in every machine”. His company, based in Cham in Switzerland, develops and manufactures soldering systems for the electronics manufacturing world and constantly strives to set new standards such as The Modula or the Jet Wave. There are over 2000 systems worldwide making diverse products for most of the electronics manufacturing sectors. Their intrinsic qualities include the fact that they permit complex circuit boards to be soldered with great reliability. The EU moved to eliminate Pb from electronics processes – along with Cr6, Hg, Cd and some flame retardant materials – in 2006 and Kirsten Soldering AG saw this as an opportunity to develop wave soldering.

The relatively small solder pot together with its enamelled surfaces and the lack of moving parts ensured that the more aggressive Pb-free materials would have no effect on the system. Kirsten-Soldering AG is not just a Swiss company providing equipment to Europe, it is a global enterprise offering high quality and reliability all round the world.

The future and continued innovation

Kirsten-Soldering AG has maintained a strategic manufacturing alliance with Stoppani AG in Switzerland and is also supported by the Future Finance Corporation in Zug. Both finance and technical support are now available which means that growth and innovation will not stop with the advent of The Modula and future ideas and designs will follow and will include the important and patented Jet Wave technology. Kirsten-Soldering AG is definitely at the forefront of Pb-free soldering and aims to understand and work with any future EU legislation to the advantage of all its customers.

EPP Europe 413

zusammenfassung

Mit seiner weltweit patentierten elektromagnetischen Lotpumpe hat das Schweizer Unternehmen eine wesentliche Voraussetzung für ein qualitativ hoch stehendes und Energie sparendes Lötsystem geschaffen. Ein Unternehmen aus Calw, Deutschland, setzt das Hohlwellen-Lötsystem der K 7000-Serie seit Jahren in der Fertigung elektronischer Baugruppen für Nutzfahrzeuge, Hausgeräte und Industrieelektronik ein.

Avec sa pompe à braser électromagnétique brevetée dans le monde entier, l’entreprise suisse a créé une condition importante pour un système de brasage de haute qualité et économe en énergie. Une entreprise de Calw, en Allemagne, utilise le système de brasage à ondes creuses de la série K 7000 depuis de nombreuses années pour la fabrication de composants électroniques destinés aux véhicules utilitaires, aux appareils électroménagers et à l’électronique industrielle.

Con la propria pompa per saldatura elettromagnetica, brevettata in tutto il mondo, l’azienda Svizzera offre le premesse più importanti per ottenere un sistema di saldatura di alta qualità e a risparmio energetico. Una azienda di Calw, Germania, utilizza il sistema di saldatura ad albero cavo della serie K 7000 da diversi anni per produrre gruppi costruttivi per veicoli industriali, apparecchi domestici e componenti elettronici industriali.

Share: