PV systems can be assembled using a manageable number of components. Depending on the power rating of the system, the necessary components differ only in size and quantity. These components make up about 80 % of the entire costs of a PV system. Material costs can be lowered using Sunclix plug connectors, which can be installed in various sections of the PV system while on site and without the need for tools.

Dipl.-Ing. Anke Steinkemper, Phoenix Contact , Blomberg (Germany)

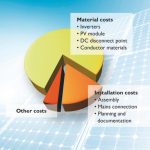

In addition to inverters, installation components, DC disconnecting points and cable material, expenditures for solar modules make up the largest part of the costs. In contrast, the installation and grid connection costs for an entire system are relatively small and decrease for larger systems. Together with the costs for planning and documentation, the installation costs including grid connection usually account for less than 15 % of the total costs.

Various types of plug connectors

The smaller the PV system, the larger the impact of material costs on the total costs. Furthermore, the share of installation costs increases as PV module prices fall. For these reasons, efficient and time-saving wiring with simple product solutions are becoming increasingly important. The interfaces in a PV system – from module to module or from module to inverter – are implemented mainly using plug connectors. Technicians are often confronted with various types of modules and inverters with different plug connector systems at these interfaces.

One thing that all conventional plug connector systems have in common is that they all use crimp contacts. In practice, different crimp contacts are used for the various wire cross sections. Special crimping pliers are required that often use a variety of different crimp inserts. The installer must ensure that the force is applied correctly. After choosing suitable contacts, the connections are made by crimping the contacts onto the wires.

Easy connections

Using Sunclix, the first tool-free PV plug connector system that can be assembled in the field, connections can be made easier than ever before. This is largely attributable to the spring-cage connection technology in use. Once the wires have been stripped, the cable can be inserted into the spring-cage connector. By pressing against the spring lever with a thumb, the connection is established once a ‘click’ is heard. The cable gland is simply laid on top and twisted.

In addition to facilitating fast connections, spring-cage technology offers other advantages. Conventional solar cables with cross sections from 2.5 mm² to 6 mm² can be connected using one and the same plug connector. Until now, numerous types of cables have been used including the H07 format, which admittedly is hardly suitable for outdoor applications lasting more than 20 years. The current trend is toward installing solar cables that comply with DKE requirements. The latter have established quality ratings that are both uniform and straightforward. UV and temperature stability specifications as well as stipulations for double-insulated cable for DC voltages up to 1000 V — these are just a few examples of the efforts that have been made to make the cable market simpler and more transparent.

Many cable manufacturers have already begun to orient their products toward these new requirements. Sunclix from Phoenix Contact is a DC plug connector that has been specially developed for what is now designated as PV1-F cabling. Common outer diameters of industrial cables ranging from 5.0 to 8.0 mm can be connected with a water-tight seal using just a single cable gland. This eliminates the need for tedious tasks such as choosing crimp contacts and cable seals that fit the outer diameter of the cables in use. It is also no longer necessary to prepare the cables and connectors while on site. Installers only have to remove the plug connectors from the packaging before making the connections.

Installation benefits

Sunclix plug connectors are manufactured in highly automated processes that ensure consistently high levels of quality even with large unit numbers. Furthermore, these plug connectors have been specially designed as one-piece components for easy installation. This prevents wiring errors and speeds up connecting times significantly. Inverters can also be connected more quickly than before. For this very last interface, cable lengths may differ and the connection is usually made directly at the device. Inverters from SMA Solar Technology take advantage of all of the installation benefits provided by the Sunclix plug connector. All SMA product ranges are being successively adapted to these new plug connectors. Thus, the various connectors used until now on the DC side of the inverters have been unified as a single system. Since Sunclix is not compatible with any of the other systems currently on the marketplace, it is not possible to mix different types of plug connectors. This noncompliance with other plug connectors is intentional and prevents dangerous combinations of materials from being used such as, for instance, silver-plated contacts with tinned surfaces on products from other vendors.

Protection against surge voltages

In addition to ergonomic and efficient cabling, efficiency and safety are also paramount in PV systems. For cost reasons, surge voltage protection is not often implemented in PV systems. Surge voltages such as those resulting from lightning strikes can cause severe damage to PV systems, which in turn can incur costs through downtime and repairs. Surge voltages resulting from lightning strikes are by no means rare and can cause fires that destroy the entire PV system. Failure to install protective components of this type to save costs may lead to higher financial losses down the road. The highly discussed topics of how fire departments should best handle fires in PV systems and the uncertainty of intervening in burning systems that are still generating current only serve to illustrate the importance of protecting tangible assets and personnel from the hazards of surge voltages.

To protect against such consequential damages, the company offers protective components, custom solutions and pre-assembled generator connector boxes. Using various configurations, PV strings can be connected to terminal blocks, DC and AC surge protection components as well as fuse terminals in IP65 housings on DIN rails. To ensure that these interfaces uphold the safety of the photovoltaic system while also being as easy to install as the SMA inverters — PV sets from Phoenix Contact can also be fitted with directly pluggable Sunclix connectors.

Conclusion

Since the Sunclix connectors can be used for various interfaces, they are suitable for a wide range of applications, which lowers the installation costs of a solar system. The product range is rounded out by solar cables, Y-splitters for parallel operation of PV modules, as well as highly automized junction boxes for modules. In combination with customer-specific generator connection boxes in the surge voltage protection field, entire PV systems can be interconnected using components from the company — all the way from the modules to the inverters.

Zusammenfassung

Der feldkonfektionierbare Sunclix-Steckverbinder wird vormontiert geliefert, so dass keine Zusatzteile erforderlich sind. Ein einfacher und schneller Vor-Ort-Anschluss ist ohne Spezialwerkzeug möglich und spart neben Zeit auch Kosten.

Le connecteur Sunclix, qui peut être assemblé sur site, est livré pré-monté ; ainsi, aucun outil supplémentaire n’est nécessaire. Il est désormais possible d’obtenir une connexion sur site de manière plus simple et plus rapide sans outil spécial, ce qui permet de gagner du temps mais aussi de l’argent.

Anke Steinkemper is Product Manager Combicon Solar of Phoenix Contact GmbH & Co. KG in Germany

Share: