Odd-form components – the bulky name alone conveys the challenge of today’s complex, cost-driven SMT placement setups: Be quick and flexible in your process, lean on operating personnel and high on Six-Sigma statistics. No miss-picks, please, no scrap, no standstill. Just a smooth running production at optimum cost. But there is a hitch: Odd-forms. They are among the last reaming vestiges of non-standard parts. They are literally sticking out from the neatly stuffed boards covered with rows and rows of standardized, flat and lightweight BGAs and flat packs, never mind the occasional small cap or DIP from earlier times.

Thus, automating the odd-form placement process has been a demanding task to make it fit for the clockwork pace of high-volume electronics manufacturing – leave alone the demand for scalability and re-configurability of systems and equipment after a job well done and transiting quickly to the next. As a result, odd-form placement still is something for the specialists. Still in the domain of a few equipment vendors who strive for the extraordinary, who achieve excellence under difficult circumstances and are not afraid to cross the boundaries from electronics to light mechanical assembly, robot-style. Take the situation of Danish pump manufacturer Grundfos. With an annual production of more than 16 million pump units, the Danish company is one of the world’s leading pump manufacturers. The group comprises 75 companies, with 44 sales companies, 12 production companies, 11 other branded companies, four new business companies and four management companies. At the end of 2006, its employees numbered 15,162 in 41 countries worldwide.

Circulator pumps (UP), submersible pumps (SP), and pumps for the industry (CR) are the three major product groups. Today, the company is the world’s largest manufacturer of circulator pumps, covering approximately 50 percent of the world market for these pumps. In addition to pumps, Grundfos manufactures the electric motors for the pumps and has a considerable production of electric motors for separate merchandising. Furthermore, the company develops and sells state-of-the-art electronics for controls for pumps and other systems. The Grundfos group is represented by companies in all parts of the world. In addition, its products are merchandised by distributors in a large number of countries. Last year, Grundfos set out to build the control electronics for its newly developed Alpha 2 circulation pump for household and light industrial heating (Figure 1).

High degree of automation

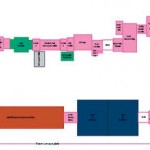

The planning went for a production of very high volumes – all to be done at their own locations in Denmark. Oddly enough, the enterprise sees no need for off-shoring and outsourcing to achieve production efficiency, all due to the high degree of automation in their manufacturing systems. Even the highly automated, final mechanical assembly of the pump itself is done at home, at a nearby Grundfos plant. To assemble the control board of the Alpha 2, Grundfos has devised a dual-lane SMT process line and a fully automated final assembly line. This setup was established in a close one-year cooperation project with Unovis Solutions charged with the sub-task of integrating three of their Polaris assembly cells. As a result, the Alpha 2 assembly process requires no manual input from operators – just feeding it with PCBs and some 120 SMT components. Fitted to the shape of the pump, the pump control electronics resides on a rounded board flanged to one of the pump’s axial sides. The board has a diameter of 80 mm. A the starting point of the two-pronged line about 66 meters in length, raw PCBs enter the process (Figure 2).

At its end, the fully assembled, tested and packed boards leave the line – at the tune of one unit every ten seconds. It’s a one-way assembly, Grundfos project manager Morten Leth Pedersen explains, with the entire process flow going in the same direction. In a way, the board is easy to assemble, Morten Leth Pedersen says, despite the fact that it undergoes a double-sided placement process.

So, at first glance, the Alpha 2 assembly line comprises the usual stations: Screen printing with air conditioning, reflow soldering with full nitrogen treatment and supply, and selective soldering. Then comes, at the centre of this case study, odd-form placement of some seven components, followed by a two-step in-line AOI inspection, ICT testing, de-paneling and press-fit. The seven odd-form components are NTCs, varistors and various large capacitors. Every day, three of the assembled control units are taken for a destructive HALT testing and another 160 units are taken for a run-in test.

Odd-form placement of some seven components

Let’s turn to the seven leaded odd-forms, such as the large capacitors owed to the pump’s power supply. They needed some special setup for feeding and placing them smoothly because they are through-hole mounted. And there lays the challenge: The rounded components require some new approaches. Especially the varistor and the NTC. Regular caps come as a square block. So, a robot grips them with two fingers, one on each side, and places them. But with those varistors, because of their rounded shape, regular grippers, which take them by their bodies, can’t really position them at the accuracy required.

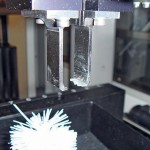

How was this resolved? By a custom solution devised in tandem by Grundfos and Unovis: The seven odd-form components of the Alpha 2 board are mounted by means of three Unovis Polaris cells (Figure 3). Two of them are of the servo gripper type with four-axis Cartesian gantry, devised to flexibly assemble all non-standard parts, including connectors, transformers, shielding and the like. The first cell places the round NTC’s and the varistor – the two most demanding rounded odd-forms. It has a specially designed gripper (Figure 4). The second Polaris, also a servo-gripper machine, is a quite regular one. It places two large caps.

Now to the third Polaris cell. It is of the multi-gripper, multi-process type and was designed by Unovis to automate traditional end-of-line assembly processes, including dispensing, vision inspection, screw driving, bar-code reading, labeling, etc. In the Grundfos setup, it features a custom-made gripper, with three grippers in one axis specially developed for Grundfos to mount three different parts. The robot activates all feeders at the same time and picks up all three parts at the same time. Unovis calls this “gang picking” – meaning all three components are picked up in parallel but then placed sequentially (Figure 5).

Special feature

The three components are caught at the body. All three grippers have the special Unovis floating head including the floating multi-process head just like standard servo-gripper machines. This special feature was devised by Unovis for Grundfos, Morten Leth Pedersen says. Between Grundfos and Unovis, it took some intense joint work to devise this custom system. “We had some ideas and presented them to Unovis,” Morten Leth Pedersen says. “They developed the fingers and sent the drawings to us for review.” The design started last September, the first acceptance test took place in Binghamton around the 26th of March. It was a remarkably smooth design process, Morten Leth Pedersen says. The result: The robot is more or less standard. With one exception: “They had to produce the feeders and grippers for each of those components. Also, the cutting tool was too small for most of the bulky, legged parts.” Another problem, Morten Leth Pedersen says, initially showed up: Scrap rate. If the Polaris picks up an odd-form part and it doesn’t hit its intended placement holes first time around, it picks the next part and scraps the first one into a scrap bin.” Good or bad? Good, of course, Morten Leth Pedersen says, because it doesn’t halt the line. “But if every other component is scrapped, it gets quite expensive and slows down the line.” The solution, quickly found: Each gripper is designed for the component it has to pick and the Unovis machines have feature to retry in circles to hit the hole before the part is scrapped. At this point, the production line at Grundfos is up and running, producing to fill up inventory for the time the Alpha 2 will hit the market.

Cutting down power consumption

For Grundfos, which dominates the world market of household and light industry circulation pumps by a comfortable share of 50%, the new Alpha 2 was an ambitious project when it got underway last year. Alpha 2 is to complement and succeed its extremely successful predecessor, the Alpha PRO, which has been in production since 2005. Both, Alpha PRO and Alpha 2, are Grundfos‘ first “Energy Class A” rated circulation pumps. (Typical circulator pumps in European homes today have an energy efficiency corresponding to Class D or E.) Alpha PRO has three selectable speeds, two constant-pressure as well as two proportional-regulation curves. Its power consumption ranges from 50 W down to 5 W.

To meet Grundfos‘ declared environmental commitment – and the EU’s across-the-board energy savings mandate of 20 % by 2020 as well – pump power had to substantially come down. “Alpha 2,” says Morten Leth Pedersen, “can cut the power consumption of heating-system pumps down to 5 W.” That’s quite a jump up in efficiency, by almost one order of magnitude. To do this, the new pump automatically adapts its power consumption in real time to the actual demand of heating in the system in which it is installed. It does this by continuously measuring the flow of water in the pipes it is connected to. This is all the more important if you consider that Grundfos‘ circulation pumps are found in every other household heating and warm-water installation throughout Denmark and much of continental Europe. With their new Class A pumps, the company is set to contribute to future energy savings of 400 MWh per year.

EPP Europe 428

Polaris assembly cell

Among Unovis‘ specialized solutions for the odd-form placement process in various manufacturing environments, the Polaris assembly cell is signified by its flexibility and scalability. The Polaris concept was devised to automate electronic as well as light mechanical assembly procedures in high and low volume production. Components such as connectors, transformers or other non-standard parts can be migrated onto the Polaris servo gripper assembly cell. It features a 4-axis Cartesian gantry and a gripper head with a vacuum spindle. Mechanical assembly tasks, including adhesive dispensing, vision inspection, driving screws and packaging tasks, are performed by the Polaris multi process cell. It carries up to three independent tool modules and features image acquisition and inspection to combine SMT with through-hole mounting. For final assembly tasks, bordering on robotic and semiautomatic production tasks, there is the single-process odd-form cell, based on the Polaris Junior machine. This cell enables scalable widths from 500 mm up to 1500 mm. It comes with common controls and a frame structure for low-cost environments, compatible with regular conveyors. Grippers and feeders, as well as standard tool interfaces, are reconfigurable to quickly accommodate different assembly projects. Unovis also provides and co-designs custom tooling – as was the case in the Alpha 2 control board assembly for Grundfos, which required the placement of NTCs, varistors and large capacitors.

Polaris cell machine

zusammenfassung

In Kooperation mit dem dänischen Pumpenhersteller Grundfos hat Unovis Solutions eine Assemblierungslösung für dessen Wasserpumpe Alpha 2 (Energieklasse A) entwickelt. Neben 120 regulären SMTs erfordert die Steuerschaltung der Pumpe das Platzieren von sieben durchkontaktierten Oddform-Komponenten. Der Assemblierungsprozess auf einer vollautomatischen Montagelinie involviert drei Polaris Assembly-Zellen, einschließlich der Multi-Process Polaris, in einer speziell für “Gang-Picking” konfigurierten Version.

En association avec le fabricant de pompes danois Grundfos, Unovis Solutions a développé une solution d’assemblage pour la pompe à eau Alpha 2 (classe énergétique A) de cette société. Outre 120 composants TMS, le circuit de commande de la pompe nécessite la mise en place de sept composants exotiques («oddform») traversants. Le processus d’assemblage sur une ligne de montage entièrement automatisée met en œuvre trois cellules d’assemblage Polaris, y compris la cellule Polaris Multi-Process, dans une version spécialement configurée pour le «gang picking».

In collaborazione con il costruttore di pompe danese Grundfos, Unovis Solutions ha sviluppato una soluzione per l’assemblaggio delle pompe acqua Alpha 2 (classe energetica A). Oltre ai normali 120 SMT, il circuito di controllo della pompa richiede il posizionamento di sette componenti odd-form con contatti passanti. Il processo di assemblaggio su una linea completamente automatica prevede tre celle Polaris Assembly, compreso il Multi Process Polaris, in una versione speciale configurata appositamente per “Gang-Picking”.

Share: