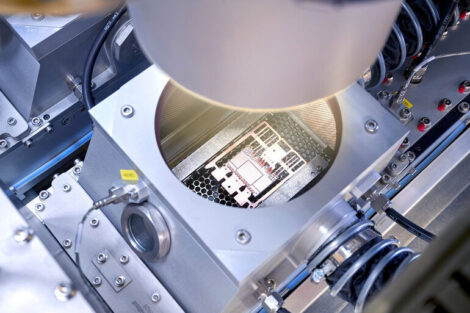

The need for wave soldering in electronics manufacturing continues, with evolving process challenges and the need for high yields and 24/7 reliability. Vitronics Soltec has introduced the Delta flexible wave soldering platform, designed to deliver high yields and throughput while minimizing down time and cost of ownership. The new platform embodied in Delta models 5 and (larger unit) 7 is characterized by tighter process control and flexibility in virtually every aspect of the wave soldering process.

For example, a friendlier operator interface, called EasyUse, makes programming, setup, and process changes easier and the entire process more configurable. Strictly controlled preheating and fluxing, plus a more tightly controlled wave soldering process and atmosphere control make the new platform fully lead-free capable. Legendary Delta reliability, plus an easy-maintenance design make the new series the pinnacle of wave soldering technology evolution, advancement, and design for performance.

This flexible wave soldering platform has evolved over generations of equipment, from thousands of machines in the field. It is a simple to set up and operate, reliable, dependable and cost-efficient wave soldering machine. It gives the customer exactly what is wanted: low cost of ownership, high yields, ease of use, and 24/7 repeatability and reliability. Automatic removal of dross, chipwave nozzle open access, and a unique separate dross compartment all contribute to optimizing preventive maintenance procedures.

Closed loop fluxing, preheating, and wave height measurement ensure a stable process as well as efficient delivery of high first-pass yields. The Delta 5 and 7 are more of a ‚process instrument‘ than just another soldering machine.

EPP Europe 417

Share: