PRO Design Electronic in Bruckmühl is a full-service solution provider from the idea to the finished product. Its customers come predominantly from high-quality markets, such as the automotive, medical technology, aerospace and semiconductor industries. In addition to providing production services, the company offers its own family of “proFPGA” prototyping products. They do not just manufacture for others, but also focus on product development and layout. Over more than 30 years, the company has become known for its expertise in highly complex product designs that meet the highest technical requirements. To be ready for the future and to meet its rising order volume, the company decided last year to add a new production SMT line to its factory. At the end of the evaluation process, ASM came out as the winner. The new DEK NeoHorizon printer and the three new Siplace SX machines impressed the decision-makers with their high precision and reliability thanks to the state-of-the-art Siplace vision system. Quick with simple programming, the ease with which new components can be described, high feeder capacities and simple programming via a clear, German-language user interface were additional factors in favor of ASM. The SMT line also features a new Rehm oven with vacuum technology for shrinkage-free soldering.

High-mix production handles various components and FPGA chips

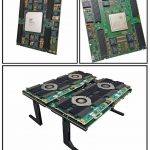

With the company’s specialization in complex products designs, the jobs PRO Design Electronic runs in its internal SMT production and tend to be characterized by a high degree of component diversity and density. 400 different products are manufactured on two SMT lines, including circuit boards with up to 4,500 components and 200 different component types. Components of size 01005 are nothing special, and BGA pitches can be as small as 350 µ. All of this is no problem for the printer and the placement machines. Since the installation of the new SMT line, the companies printing quality has increased significantly, and the new printer is much more flexible than the old equipment. “Our production is incredibly diverse. Our own products as well as those of our customers demand versatility and precision. Some of our jobs involve very expensive components, which is why the SMT line is not allowed to make mistakes. In addition, we need high feeder capacities, because our frequent setup changeovers require us to be quick and flexible. ASM’s line concept convinced us completely. The three Siplace SX machines provide roughly 360 feeder slots,” explains EMS provider CEO Gunnar Scholl. “High-volume components stay on the line, and fast setup changeovers can be executed with great flexibly thanks to the random setup capability of the company. Even 01005 components as well as exotic and unwieldy shapes can be handled with ease. We can even get the stencils for our more complex boards from ASM. They meet all of our needs to the fullest.”

Faster, minimal downtime, and a technology partner that is always available

The flexibility of the new SMT line was apparent from the start. Since the EMS provider was still building a new production hall for it at its plant in Bruckmuehl, its people could start training and run some initial products on a standalone solution with a two-gantry Siplace SX in its existing plant. As soon as the new building was completed, two more placement machines were added and the gantries reconfigured. The production could start right away. And since the second SMT line continued to operate, there were no production interruptions.

“Switching to an entirely new system with the new machines was a challenge for our line staff, of course. But ASM safely supported us throughout the training process, and we are very happy and satisfied with the modern and speedy programming options for the printer and the placement machines,” says René Dösinger, Head of Production Planning at the EMS provider. “ASM’s support was also quite impressive. Having the SMT Center of Competence so close by in Munich was especially helpful. During our visits we learned a lot from their experts and were kept up-to-date on the latest technological and functional developments.”

“The conversion to ASM was a complete success,” summarizes Scholl. “With a little more practice, our setup changeovers will become even faster in the future. But we can already state that the new line enables us to produce roughly 30 percent faster than before while meeting all our customers’ quality requirements. We do not regret our decision in favor of ASM.”

For the future, the EMS provider plans to add high-performance computing to its business as a third segment. With its flexible gantry concept, the new SMT line can easily accommodate this growth. Another project on the agenda: “Today all production steps are linked and affect each other. In a high-mix environment like ours, the material management must function seamlessly, which is why we want to take a look at the Material Manager and other options very soon. An integrated warehousing solution will give our productivity another significant boost,” says Dösinger.

SMTconnect, Booth 5-311

www.asm-smt.com; www.prodesign-europe.com

PRO Design Electronic GmbH

With over 100 employees, PRO Design Electronic has manufactured electronics products for an international customer based in high-quality markets like the automotive, medical technology and semiconductor industries for over 30 years. As an EMS provider, the company offers the complete spectrum of services for consulting, development, layout and prototyping and volume production. The company specializes in demanding designs with high component densities, complex shapes and diverse components ranging in size from 01005 to 200 x 120 mm. The company also builds its own line of “proFGPA” prototyping systems that are based on FGPA technologies. The systems, which are used for testing new chip designs and their corresponding software, require the high-quality placement of especially expensive components.

With its new production line consisting of a DEK NeoHorizon 03iX, three Siplace SX machines and two new Rehm reflow ovens with vacuum technology for shrinkage-free soldering, the company produces its jobs 30 percent faster than before with minimum downtime and zero placement errors.

Zusammenfassung

Ein EMS-Dienstleister erweiterte seinen Maschinenpark um eine neue SMT-Linie mit Schablonendrucker sowie drei Bestückmaschinen desselben Herstellers. Der Fokus bei der Auswahl lag dabei auf gesteigerte Qualitätsansprüche, hohe Genauigkeit und Flexibilität bei einem vielfältigen Produktmix.

Résumé

Un prestataire de services EMS a élargi son parc de machines avec une nouvelle ligne SMT, qui contient une imprimante a stencil et trois machines de placement du même fabricant. La sélection s‘est concentrée sur un besoin d‘exigences accrues en qualité, précision et flexibilité, dans une gamme diversifiée de produits.

Резюме

Разработчик микроэлектронных схем расширил свой парк оборудования за счет новой линии поверхностного монтажа с трафаретным принтером, а также тремя автоматами для установки компонентов того же производителя. Выбор был обусловлен возросшими требованиями к качеству, высокой точностью и гибкостью при работе с широким спектром продукции.