Asymtek announces its Axiom X-1022 Dual-Lane dispensing system to maximize throughput during multi-pass underfill operations. The dual-lane system increases the number of units per hour (UPH) produced in high-volume semiconductor applications such as flip chip and chip scale package (CSP) underfill.

The X-1022 allows parallel processing on two lanes for continuous dispensing, eliminating lost time in non-dispensing activities, such as material flow-out and substrate loading and unloading. In some applications, a 60 to 80 percent increase in throughput over single-lane dispensers can be achieved.

The dual-lane capability allows underfill flow-out in one lane while jetting underfill in the opposite lane. The conveyors are independently controlled, allowing different-sized parts to be processed in lanes one and two for ultimate process flexibility. The programmable flat-belt, dual-lane conveyor allows for a variety of process carriers, including Auer boats, lead frames, and custom carriers.

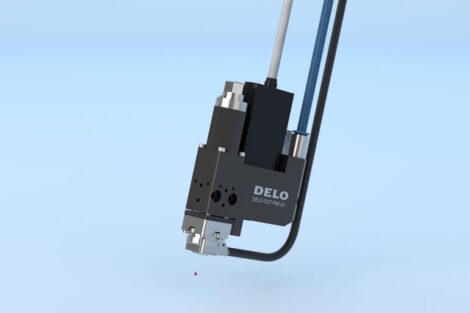

The Axiom dual-lane system uses the company’s patented jetting technology.

EPP EUROPE 441

Share: