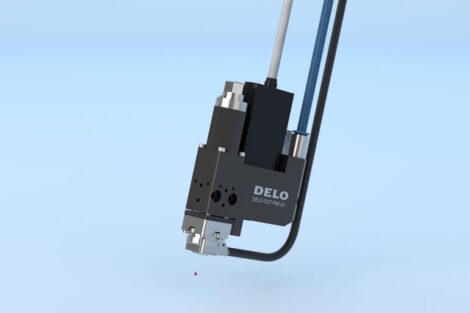

Jet Pro flux valve is part of Unitek Eapro‘s Jet Pro dispensing system that fully complies with the requirements of the production environment of today: more precise, faster and smaller fluid deposits. The valve series is suitable for a wide range of different fluids, like e.g. conformal coatings, oils, greases, adhesives, and inks. This valve type was designed to increase the overall performance, combining high speed, precise fluxing with pulsed heat selective soldering in one production cycle.

The Jet Pro flux dispenser system comprises a very small, piëzoelectric light weight valve, a dispenser and a controller. The piëzo technology of this valve type guarantees very short dispense times (³10 µs) and allows for extremely small deposits (down to 0,002 µl). Dispense cycles up to 300 g/min are certainly achievable. Also for this specific flux version of the Jet Pro series the long life time is a benefit. A tight fitting 150 µ nozzle of high quality ceramics and the piëzo actuator stand for high reliability and extremely precise dispensing. Compared to traditional time pressure (spray) dispensing, the high precision of Jet Pro flux dispense system eliminates “overspray risks” up to 100 %, and at the same time reduces cycle times in many cases. The valve allows for distances up to 3 cm without losing precision. This distance also eliminates the need for extra automation: less of no need for z-motion in automated systems. Additionally, when fluxes with a solids content of more then two percent are applied, the dispense pattern of the jet valve remains precise and consistent, which is not the case with regular spray valves.

EPP EUROPE 428

Share: