Design innovations certainly owe much to advances in technology, evolving marketplace trends like smaller, thinner, and lighter, the particular or unique requirements of an application, and many other interrelated influences. Design engineers additionally play vital roles as innovators when they strive to attain a “lower assembled cost” for their designs, in effect achieving more with less. This is an especially critical objective in a challenging economic environment where manufacturers wrestle constantly to increase productivity and profitability without adversely impacting end-product integrity and quality.

Jay McKenna, PennEngineering, Danboro (USA)

When designers begin the task of decision-making for methods to attach assemblies and components, the process sometimes can suggest different (and innovative) approaches offering newfound benefits. Maybe fastener parts count (and costs) can be reduced; perhaps assembly time and/or steps can be shortened; or more reliable attachment can be realized. While every application presents its own inherent challenges, there is no shortage of fastening solutions in the designer’s toolbox of technologies. Examples from our customer applications casebook tell the story.

Assembly technology

Typically in the case of heat sinks, the mounting process will involve loose hardware to inventory, handle, and install and force designers to confront a range of other issues. These include the need for pre-drilled holes or tapping, the potential intrusion of installed fasteners into the “cooling fin” side of a heat sink, and “slug” or scrap resulting from the installation process. All can detract from the goals of efficient heat sink design and economical assembly. Proprietary Surface Embedding Technology (S.E.T.) fasteners introduce a practical way to resolve virtually all the problems encountered with conventional hardware. These versions of steel or stainless steel fasteners in various styles have been engineered to mount permanently on one side and leave the reverse side unaffected. Their specification can reduce or completely eliminate loose hardware and allow for automated fastener insertion, smaller packages, and more streamlined production down the line.

Making face-to-face contact

When an application requires two thin metal sheets to be joined permanently face-to-face, designers often may consider rivets, welding, or adhesives and tapes. But each of these methods carries tradeoffs. Whilst welding seems a natural method for joining two sheets of the same type of metal, it is virtually impossible when joining dissimilar metals, such as steel to aluminum. If the welded surface is intended to be the finished surface, then additional finishing steps due to burn marks and scale will be required to create a presentable “cosmetic-friendly” assembly. Riveting can work more effectively for attaching dissimilar thin materials, but rivets cannot install flush with a finished surface, leaving unsightly metal bulging often limiting their use to utilitarian assembly inside enclosures. Since rivets do not finish flush, attention must further be paid to the clearance necessary for the rivet bulb. The bulb can rob valuable “real estate,” especially in applications where space is at a premium. Adhesives and tapes fulfill requirements for clean and flush attachments, but their downside is a relative lack of strength compared with the other methods. Users quickly discover that epoxies can be messy; double-sided tapes can be cumbersome; and tapes and adhesives can fail when exposed to extreme heat. These issues have given rise to the development of a unique clinch fastener design offering a more practical and less complicated joining method with the added capability to perform multiple functions and expand design possibilities. The non-threaded fasteners permit two metal sections to be joined permanently and flush to create a smooth-finish surface. Users can marry two dissimilar metal types and sheets of unequal thickness or even metal panels to plastic sheets. An added advantage: The fasteners can perform as flush-mounted hinges or pivot points, whereby the top sheet rotates around the fastener while the bottom sheet remains stationary.

Becoming wired inside the box

In the case of mounts to hold ties for wires or cables within enclosures or electronic chassis, designers likely may cross their fingers that mounts will be located where specified, remain in place, and require minimal hardware for installation. Plastic adhesive-mounted bases for these applications can fail over time and temperature cycling; snap-in or screw-mounted bases will require the use of screws and more time to install; and lances in sheets will open the door for EMI/RFI or contamination by dust or dirt. A family of self-clinching cable tie mounts and hooks represents a different, relatively more practical approach to create permanent attachment points without screws or adhesives. Their locations and positions can be set during the design process to provide optimal layout for wires and cables during final assembly. Ties slide easily through the “eye” in mounts and hooks can be used to attach, remove, and return tie-bundled wires at their mounting points when components need to be accessed for service or when wires or cables must be replaced. The hook feature allows ties to remain intact and wires to remain wrapped. Both types of hardware by their permanent installation remain reliably fixed and secure at designed locations. The flush design also allows the user to maintain the smooth appearance and integrity of the enclosure.

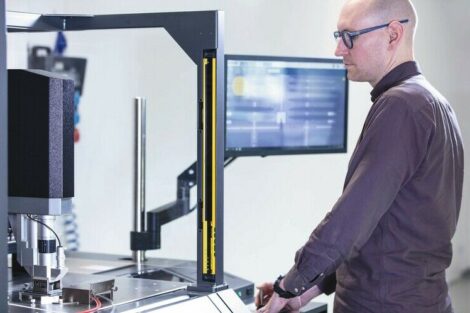

Performing at level best

A laser-leveling device developed by a manufacturer incorporates a rotating laser beam. The laser is placed on a bracket that floats on springs, which ensures that the laser beam is always horizontal, performing as a gyro. Special weld nuts for mounting were causing several problems in the assembly of the gyro, including misplaced studs, studs placed in an angle other than 90º, and weld spatter. All adversely affected the gyro’s function. Design engineers turned to self-clinching studs to replace the weld types, which solved the problems and contributed to a cleaner assembly process.

Achieving more with less

The printed circuit board for a line card in a manufacturer’s optical fiber telecom equipment presented the challenge of spacing and securing mother board to daughter board. The conventional method to secure both boards had been grounded in the use of significant amounts of loose hardware. Assembly of these boards inevitably became slow and inefficient. Designers analyzed the issues and specified steel surface-mount spacers to replace the loose hardware. These install permanently on printed circuit boards in the same manner as other surface mount components prior to the re-flow solder process. Their use inevitably reduced the risk of damage to boards that occurred when conventional fasteners were improperly installed with off-line equipment; minimized the number of loose parts and their handling; and promoted quicker assembly by eliminating secondary operations.

Measurable benefits realized in this application included hardware reduction by 50 % and cost reductions greater than 50 % compared with manual assembly. The boards also are now handled less, which has improved overall reliability in the high-cost units.

Footnote: When design engineers are able to take a “fresh look” and evaluate how and why attachment is (and could be) accomplished, often more practical solutions can emerge, as underscored by the profiled applications. This recognition has led to the introduction of our PEM Cost Savings Investigation (CSISM) Program, which is a free service to assist designers in potentially reducing their total “assembled cost” of products and designs.

Here’s how CSI works: Program teams completely disassemble any supplied product and document every procedural step in writing and with photographs as evidence. When the investigation is concluded, a comprehensive and confidential report is developed and submitted with recommendations to help improve overall assembly costs. Strategies may deliver reductions in loose hardware, production steps, and/or assembly time.

Share: