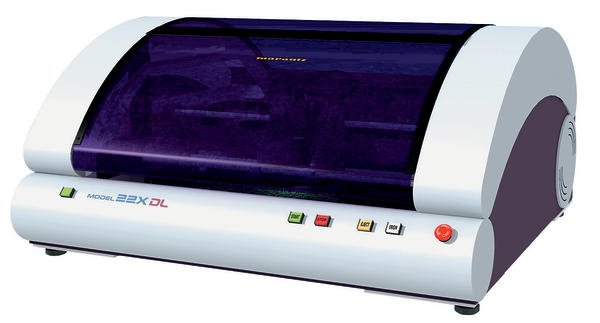

The M22XDL350 desktop Automatical Optical Inspection machine from Marantz Business Electronics supports comprehensive inspection of PCBs, including SMT and THT components, reflow and wave solder joints, and solder paste. It features the smallest footprint of all the machines in the firm’s range of destop AOI systems. Building on the strengths of the company’s CL systems, the 22XDL generation introduces a new lighting concept, with 3 Pulse Wave Modulated LED light sources and up to 6 different lighting combinations enhancing operator control for exceptional inspection accuracy. This operator control is enhanced by Rep 22X Statistics and Repair Desk Software. Actively collecting inspection data from any 22X AOI machines in the network, the software is able to monitor the inspection process in real time while simultaneously visualising collected data. This functionality can be applied to each PCB for repair purposes or collectively to generate process statistics and analysis, maximising operator visibility and knowledge throughout the entire inspection process.

Visitors to the firm’s Nepcon stand can also find out more about the in-line AOI system L22XDL-520. Uniting fast programming, reliable detection and true 24/7 operation on a single platform, the in-line offering is equipped to deliver near 100 % uptime and enhance operator control.

SMT, 9-634/Nepcon, stand M80

EPP Europe 478

Share: