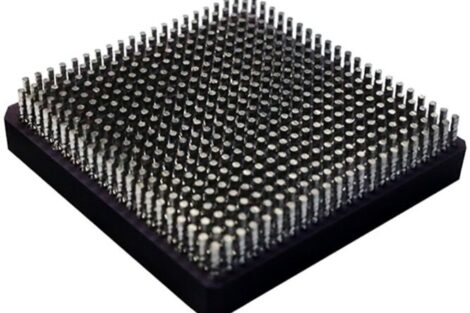

Vitrex AT200 and Vitrex-CA from Aqueous Technologies Corporation The Vitrex de-fluxing chemicals are designed to remove all flux types from post-reflowed circuit assemblies. They are cleaner/de-fluxers, providing thorough cleaning while also ensuring bright, shiny solder joints. Unlike many other chemicals that require sump-side additives (de-foamers, brighteners), Vitrex AT200 does not require any additives. Additionally, the cleaner offers high-loading chemistry designed to operate at temperatures between 100 º to 150 ºF (37 º to 65 ºC). Although it works very well at diluted concentrations of 10 percent, its operational range is between 5 and 30 percent. Its compatibility with a large range of operational parameters provides an extremely wide process window, ensuring its suitability with almost any de-fluxing application.

One of the major benefits of the cleaner is the way it leaves the solder joints with a brilliant finish. Also, it may be used on multiple-pass cleaning applications (applications that require a board to be cleaned more than once).

Vitrex-CA is a specially designed low-VOC, MEA-free aqueous blend designed for optimum performance on reflowed solder pastes (no-clean, rosin, lead-free), tacky fluxes and uncured adhesives. Unlike other chemistries that produce dull solder joints, the chemical produces brilliant (shiny) surfaces. It is an “all temperature” product, providing effective cleaning results at operating temperatures between 110 ° to 160 °F (43 ° to 71 °C). The Chemical is a non-flammable, low VOC, low-foam, non-corrosive chemical. Vitrex-CA is cost effective with no sump-side additives required and a long bath life.

The chemicals have been tested on a large selection of solder pastes, and in-depth cleanliness evaluations have been preformed and documented. Vitrex compatibility and cleanliness studies are available online on the company’s Web site.

Nepcon UK, H20

EPP Europe 456

Share: