With all the different Pb-free solder pastes on the market today, how does anyone choose the correct solder paste that will ensure finished goods reliability? The answer lies within the hands of the experts. A few quick phone calls to the solder paste manufacturer and you will be building Pb-free printed circuit boards in no time. So you’re ready to start. There are some parameters and information that your expert technical support engineers will need to know in order to help you choose the perfect solder paste for your specific application. These engineers will use their knowledge of the products and the process to recommend the correct alloy, flux vehicle, mesh size, metal load, and packaging method based upon the information you provide. Once this information has been determined you’ll be off and running with your sample of Pb-free solder paste.

Solder manufacturers have multiple choices available for both no-clean and water-soluble solder pastes. Pb-free solder pastes have evolved over the years. Wetting, solder balling, solder spatter, voiding, and halide content, are among the many challenges the industry has faced during the conversion from the more commonly used SnPb solder to Pb-free solder. Each challenge presented the opportunity for more innovative solutions and the development of new solder pastes. However there may never be a “silver bullet” solder paste – that is, one solder paste that functions perfectly in every application. Therefore, it is important to decide which challenges pose critical threats to your products and process and focus on choosing a solder paste that has strengths in those areas.

The correct alloy

With hundreds of alloys available, choosing the ideal Pb-free solder alloy for your application can be the most difficult part of the process. Many companies continue to follow the industry and use a SAC or Tin/Silver/Copper (Sn/Ag/Cu) alloy for their Pb-free applications. SAC 305 (96.5 Sn/3.0 Ag/0.5 Cu) has emerged as the predominate alloy, but SAC 387, SAC 105, and SAC 405 are also becoming more popular. Pb-free choices are not limited to the SAC alloys, however. Indium- or Bismuth-containing alloys are suitable for low temperature processes, while Gold-containing alloys, like 80 Au/20 Sn work best in high temperature applications. In order to determine which alloy is the best fit for your application, your technical support engineers will need to know the following information:

- What is your ideal alloy melting temperature?

- Are there temperature constraints with your board or component design?

- What metallizations you are soldering to?

- Do you need a Pb-Free alloy?

The answers to these questions will help you to choose the appropriate alloy for your specific application.

Flux vehicle

Once you select an alloy, the next step is to determine the best flux vehicle. The choice between water-soluble or no-clean materials is usually based on what you have used in the past and what equipment you already own or may be purchasing. Many times, especially with contract manufacturers, the customer will determine whether the finished circuit boards need to be cleaned or not, and may even specify the flux type to use. Water-soluble materials differ from no-clean materials because the flux residue, after reflow, must be washed off. No-clean flux residues, after reflow, are benign and do not need to be washed off the board. However, more and more companies are cleaning the no-clean residues to obtain a more appealing cosmetic appearance. The no-clean residues can be cleaned with a commercially available flux cleaner, whereas the water-soluble residues can usually be cleaned with just DI water. When cleaning any flux residue, you will want to make sure it has been removed completely to avoid reliability concerns and other issues regarding the future of the circuit board and/or the product.

The solder manufacturer will have multiple choices available for both no-clean and water-soluble solder pastes. Solder pastes have evolved over the years. The choices that are available now include new and improved formulations that may have emerged due to new challenges that have presented themselves to the industry. It is important to decide which challenges are the most critical to you and your application and look for a solder paste that will work best to resolve those issues. Even if you are not experiencing some of the issues that the new formulations have been developed to overcome, you never know what you will run into in the future. It is always a good idea to be as prepared as possible for any challenges that may arise.

Mesh size

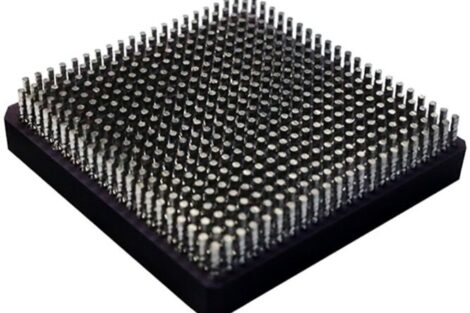

The next thing you need to consider is the mesh size, or the solder powder particle size. The selection of the appropriate powder size for a specific solder paste application is a fundamental step that will ultimately affect the printability of the solder paste with respect to the stencil design. Stencil design, focusing specifically on area ratio, plays an even more crucial role in solder paste printability.

Area ratio is essential to the printing process and powder choice. Calculating the area ratio and choosing the correct powder size can help ensure proper stencil release. The area ratio is the ratio between the area of the aperture opening and the area of the aperture walls [area of the opening/area of the walls $ 0.66]. Once the proper aperture size has been determined, the appropriate powder size can then be chosen. For all apertures, it is important to maintain a minimum of 4 or 5 solder particles (the large particle size of the range) across the aperture. The chart on the previous page can help serve as a guide.

Metal load and packaging

The next step is to choose the packaging, which will ultimately determine the metal load. Many different containers are available, including jars, cartridges, syringes, and proflow cassettes. With the exception of the proflow cassette, all of these packages come in a variety of sizes to suit your usage and preference. The metal load is the weight percentage of metal in the solder paste. This is typically determined by the specific flux vehicle, mesh size, the packaging method, and the solder paste manufacturer’s experience and expertise. The metal load is typically within the range of 88 % to 91 % for printing and 83 % to 87 % if the material is being dispensed from a syringe. It is always a good idea to let the solder paste manufacturer determine the metal load because they are the most familiar with what percentage will work the best for the specific application and solder paste.

Testing

Now that you have nailed down the necessary parameters for your ideal Pb-free solder paste, it is time to get samples of each paste that fits your requirements and then test them against each other to find the absolute best fit for your soldering needs.

However, before you begin, you should create a Design of Experiment (DOE) to ensure that the correct testing is performed. The DOE should be set up to test all aspects of the solder paste process, including, but not limited to, printing, component placement, reflow, and cleaning (if cleaning will be performed). Once you have drafted the DOE, the test results will determine the appropriate Pb-free solder paste for your production process.

Conclusion

Choosing the correct Pb-Free solder paste for your specific soldering application can be a challenge. Luckily, there are experienced people that can help you choose the correct alloy, flux vehicle, mesh size, metal load, and packaging method for your process. In addition, they can help you create a DOE to ensure the product you choose is right for your needs.

SMT, booth 7-430

EPP Europe 429

zusammenfassung

Die richtige bleifreie Lötpaste für eine spezifische Anwendung auszusuchen, kann eine Herausforderung sein. Es gibt einige Parameter und Informationen, die Ingenieure im technischen Support benötigen, um die perfekte Lötpaste für eine bestimmte Anwendung auswählen zu können.

Le choix de la pate à souder correcte exempte de plomb pour une application spécifique constitue parfois un véritable défi. Pour pouvoir choisir la pate à souder convenant parfaitement à une application spécifique, les ingénieurs de l’assistance technique doivent connaître certains paramètres et posséder certaines informations.

Può essere difficile scegliere la pasta per saldatura prova di piombo adatta per una data applicazione. Per questo gli ingegneri dell’assistenza tecnica necessitano di alcuni parametri ed informazioni.

Share: