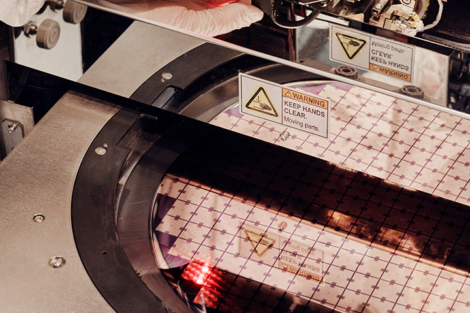

Wire bonding is a method of making interconnections between a microchip and other electronics as part of semiconductor device fabrication. Bonding machines use “ultrasonic energy” “force” and “heat” to connect wires with a surface. Since 1996 TPT has designed and manufactured a range of manual and semiautomatic wirebonders. The company is located in Karlsfeld near Munich, Germany. The bonders have proved themselves in laboratories, in prototyping and in batch production. EPP Europe spoke to Franz Hickmann, the founder and Managing Director of TPT about the products of his company.

Mister Hickmann, what precisely does your company manufacture?

We manufacture manual and semiautomatic wire bonders. Our bonders are capable of doing wedge bonding, ball bonding, stud-Bump and stitch bonding, and process even ribbons. Supported wire sizes are 17 µ to 70 µ Gold and Aluminium wires as well up to 25 µ x 200 µ Gold ribbon. Our heavy wire bonder HB30 processes 100 µ up to 500 µ Aluminium wires.

Which product did you launch recently?

Our newest product is the HB16D wire and die bonder.

What characterises this bonder in particular?

This device can run as a wire bonder and as a die bonder. Changeover between the bonding modes is quick and easy just by changing the bond tool type and selecting the appropriate software program. We demonstrate this in the video Die bonding at www.tpt.de.

Who benefits most from the new concept, and for what reasons?

All R&D departments as well as institutes and universities working in the field of microelectronics profit from this new concept. The only thing they have to do is to purchase such a device. With the help of it the work of two can be done. And this means fewer costs and lower space requirements.

What kind of application is the bonder suited for in particular?

TPT-Bonders prove themselves in laboratories, in prototyping and in batch production. Our customers are universities, technical colleges, institutes as well as the semiconductor and electronics industry.

What else do you have in your product portfolio?

We have three groups of products:

1. Manual wire bonders without motorized axis 2. Semiautomatic bonders with motorized Z-axis 3. Semiautomatic bonders with motorized Z- and Y-axis

What is special about your bonders?

The changeover between ball and wedge bonding is very easy: Change the bond tool type, thread the wire through the bond tool and select the appropriate bonding program. Due to the vertical bond head movement and to the Touch-Down-Sensor the bond head detects the bond heights by itself. Stage adjustments for different bond heights are not necessary. With the loop profile software 100 stage loop profiles can be saved. Each profile can consist of up to ten steps.

Furthermore, our bonders possess deep access and feature a long reach bond head. A long reach transducer, with the wire clamp positioned above the bonding tool provides excellent clearance for deep access and large area bonding. The bond arm length is 165 mm. Up to 100 programs can be stored to memory and an additional 100 programs can be backed up to an USB-memory. Precision tail-lengths are achieved by the use of a sophisticated motorized wire clamp. All our models feature a motorized wire spool for a better loop control. This means that there is no un-reel load with thin wires, and no wire twisting during the reel.

The 6,5” TFT Touch Panel User System enables fast and easy access with digital adjustment of all bonding parameters. All ball bonding capable systems also incorporate a stud bump bonding mode. In addition, with models HB 14 & 16 one can adjust the bump distance.

Could you tell us a little about your company?

TPT company was founded in 1996 by me and has been a privately owned company from the beginning. Located in the high tech area of Munich, Germany, we design and manufacture a range of manual and semiautomatic wire bonding machines. It is our goal to provide sophisticated and reliable state-of-the-art wire bonding equipment for the semiconductor and microelectronic industry. To give an example, we developed the first bond head that worked in both modes – the wedge and in the ball bond mode – and that only requires the changeover of the bond tool type. Today TPT has seven employees. In 2007 we delivered 67 bonders and in 2008 up to now we delivered 52 bonders. Sales and support is provided by us in Munich or by one of our several distributors all over the world.

EPP Europe 409

Share: