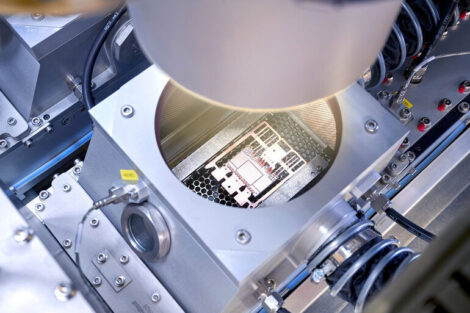

Asymtek’s Axiom X-1000 series dispensing system with a stainless steel enclosure for manufacturing in class 100 cleanrooms is specifically designed for applications that are extremely sensitive to contamination by sub-micron sized particles, such as wafer-level packaging. The system is configured to minimize particle generation within the dispense area. All pneumatic valves are exhausted to the base of the machine which optimizes ventilation within the system, and connection to the house vacuum avoids downstream particle emissions entering the cleanroom. The system’s cable track reduces particle generation, and the keyboard and mouse are enclosed in a tray mounted on a swing arm to protect the keyboard during system maintenance. An optional hepa filter can be added for downward air flow to further minimize particle generation during processing. The system is configurable for single or dual-valve dispensing to accommodate a wide variety of fluids, processes, and applications. For example, it can be integrated with stainless steel wafer film-frame or bare wafer handling equipment for ultimate process flexibility in a class 100 environment. The dispensing system uses the company’s patented jetting technology. Mass Flow Control and Calibrated Process Jetting control the critical aspects of the fluid dispensing process in a closed feedback loop. Operating within the Windows XP environment, Axiom’s FmXP software offers advancement in throughput, fluid management, and process control.

EPP Europe 430

Share: